Your Trusted Supplier of Custom Laced Wheels for Triumph Motorcycles

High-Performance, Custom Laced Wheels for Triumph Tiger & Scrambler – Built to Meet Your Business Demands

Triumph Adventure & Scrambler Laced Wheels – The Ideal Upgrade for Your Business

Looking to source premium custom laced motorcycle wheels tailored for Triumph Tiger and Scrambler models? You’re in the right place! At FLEXI Moto Wheels, we deliver everything your business needs to supply high-performance, adventure-ready wheels to your customers. Our laced wheels are engineered for strength, longevity, and off-road capability, and we offer customized solutions to meet your specific business needs—whether you’re a retailer, workshop, or distributor.

Hi, I'm Jackie from FLEXIMOTO. Let me guide you through this ultimate solutions page.

Table of Contents

Why Choose FLEXI Moto Wheels?

xpertise and Uncompromising Quality

When you partner with FLEXI Moto Wheels, you’re choosing a B2B supplier who truly understands the engineering and rugged demands of adventure motorcycle wheels. We specialize in producing custom laced wheels for Triumph Tiger and Scrambler models, tailored for businesses that demand uncompromised quality, performance, and reliability.

Whether you’re sourcing laced wheels for Triumph Adventure bikes or upgrading scrambler-style builds, FLEXI Moto Wheels offers high-strength solutions engineered to handle extreme conditions. Our wheels are crafted for:

Maximum Durability: Built for impact resistance and long-term performance across demanding terrains.

Enhanced Control: Lightweight alloy construction reduces unsprung mass for smoother handling and better ride response.

Utilizing cutting-edge CNC machining and precision craftsmanship, every FLEXI wheel is built to exacting standards. Our manufacturing process ensures:

Accurate Fitment: Perfectly tailored for Triumph Tiger 900, 1200, and Scrambler 1200 models.

Premium Surface Finishes: Available in polished, matte, or anodized styles to match your build’s tone.

Strict Quality Assurance: Each wheel is fully tested for performance, safety, and visual perfection.

Your customers want more than off-the-shelf solutions—and we deliver. FLEXI Moto Wheels offers a wide range of customization options, helping your business stand out with:

Design Versatility: Choose from proven styles or submit custom layouts.

Finish Variety: Chrome, matte black, brushed aluminum, or bold anodized hues.

Custom Branding: Optional laser-engraved logos and personalized markings to align with your brand.

Wherever your business operates, FLEXI Moto Wheels ensures smooth and timely delivery. We work with trusted global logistics partners to provide reliable shipping solutions to Europe, North America, Australia, Asia, and the Middle East. From careful packaging to complete documentation, we make international fulfillment simple, compliant, and stress-free.

Global Reach: Serving workshops, distributors, and resellers across five continents.

Customs-Ready Paperwork: Accurate invoices and product certifications tailored for smooth clearance.

Reliable Lead Times: Well-coordinated production and shipping schedules minimize delays and maximize sales opportunities.

Ready to Elevate Your Triumph Builds? Let’s Talk!

Partner with FLEXI Moto Wheels to deliver premium custom laced wheels for Triumph Adventure and Scrambler models. With our focus on durability, performance, and tailored B2B solutions, we’re the trusted supplier your business needs.

📩 Contact us today to discuss your specific wheel requirements and discover how we can support your business growth.

Our Product Categories

Cast Wheels

High-performance, durable wheels for motorcycles like Harley Davidson, Yamaha, Honda, Kawasaki, Suzuki, and Vespa.

Forged Wheels

Lightweight, strong wheels for performance bikes like Harley Davidson, Indian, Yamaha, KTM, Ducati, and BMW.

Laced Wheels

Durable wheels built for off-road motorcycles, designed for Harley Davidson, Honda, Kawasaki, Suzuki, and more.

Customization

Tailor-made wheel solutions for unique designs, sizes, and finishes, compatible with Harley Davidson, BMW, KTM, and others.

Hot Products: Triumph Adventure & Scrambler Laced Wheels

At FLEXI Moto Wheels, we provide high-performance laced wheels for Triumph Tiger and Scrambler models, combining exceptional durability, precision fit, and custom styling that meets the needs of top-tier motorcycle retailers and builders.

Built Tough: Engineered with premium materials to handle the most challenging terrains.

Precision Engineered: Designed specifically for Triumph Adventure bikes for better control and reliability.

Tailored Designs: Choose from various spoke styles, hub finishes (chrome, black, anodized), and sizing to match your market preferences.

Each wheel is rigorously tested for performance, safety, and flawless aesthetics.

Partner with FLEXI Moto Wheels to expand your product line and exceed your clients’ expectations.

Estimated Costs for Custom Made Laced Motorcycle Wheels

When sourcing custom laced motorcycle wheels, understanding the factors that influence pricing is essential. Here are the key elements that determine the cost:

1)Wheel Specifications

Custom sizes, spoke patterns, and precise fitments for Harley Davidson Cruisers can influence pricing based on the level of customization required.

2)Material Choice

Our laced wheels are built with high-quality materials, including premium-grade aluminum rims and steel or stainless-steel spokes, ensuring superior durability and long-lasting performance.

3)Finishing Options

Custom finishes, such as chrome plating, matte black coatings, or anodized colors, enhance the aesthetic appeal and corrosion resistance of the wheels, adding value to the final product.

4)Shipping & Import Costs

We provide transparent pricing that includes shipping fees, and our team offers guidance on customs clearance and import duties, ensuring a smooth international transaction for your business.

With FLEXI Moto Wheels, you get competitive pricing, premium quality, and a hassle-free experience tailored to your business needs.

Estimated Manufacturing and Shipping Times for Laced Motorcycle Wheels

At FLEXI Moto Wheels, we prioritize efficiency and reliability to meet the growing demand for custom laced motorcycle wheels. Below is an overview of our streamlined manufacturing and shipping process:

1. Design and Manufacturing

The process starts with precise design and material selection. For our laced wheels, we use high-grade aluminum rims and durable steel or stainless-steel spokes to ensure exceptional strength and performance. Each wheel is assembled and crafted to meet the exact specifications of Harley Davidson Cruisers, delivering unmatched quality and reliability.

3. Custom Clearance and Loading

We handle the customs clearance process at both the origin and destination, ensuring a seamless export experience. Our expertise in international logistics minimizes delays, allowing your shipments to move smoothly through checkpoints and reach their final destination on time.

2. Packing and Boxing

Once the wheels pass rigorous quality inspections, they are carefully packed using protective materials to prevent damage during transit. Our packaging is designed to ensure that each wheel arrives in perfect condition, ready to be installed by your clients.

4. Sea and Land Transportation

Once the wheels are packed and cleared, we arrange reliable transportation by sea and land. Upon arrival at the destination port, you’ll be promptly notified to plan the final delivery. Our trusted logistics network ensures that your goods are delivered safely and efficiently.

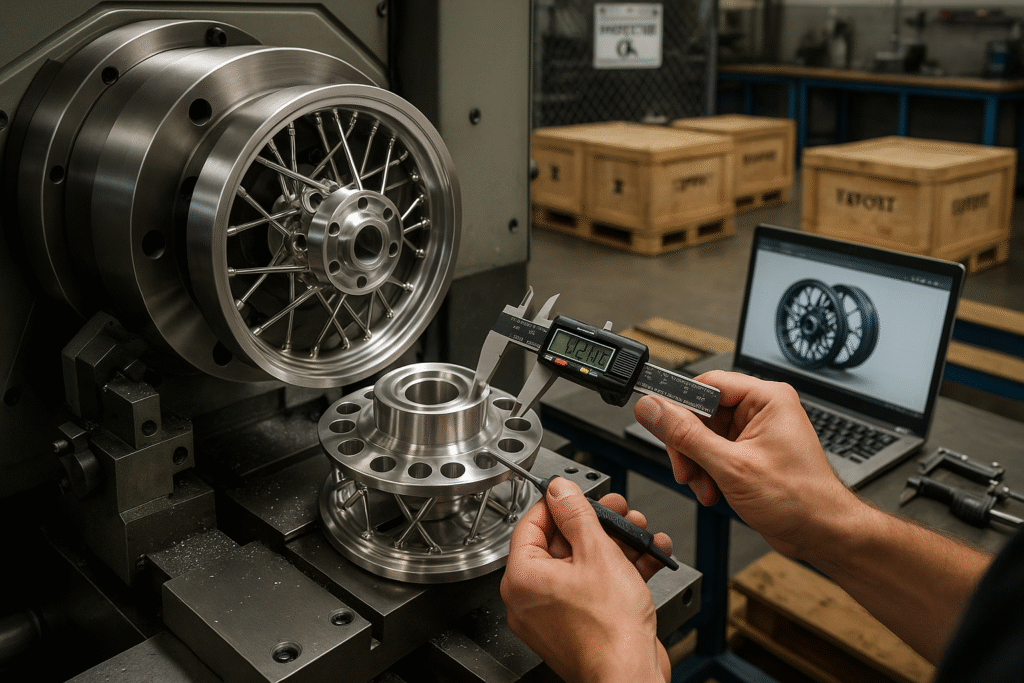

The Complete Process of Crafting Premium Laced Motorcycle Wheels

At FLEXI Moto Wheels, we engineer laced motorcycle wheels with precision, durability, and performance in mind. Designed for off-road and adventure motorcycles, our wheels are built to endure extreme conditions while offering a custom look. Here’s a comprehensive breakdown of our manufacturing process, focusing on each key component: rim, hub, spokes, and nipples.

1. Initial Design and Customer Collaboration

Every project begins with an in-depth consultation to understand your specifications. Whether you require a specific rim width, spoke configuration, or hub type, our design team creates 3D models and technical drawings. Once confirmed, we move forward with precision manufacturing.

2. Rim Manufacturing

Rims serve as the backbone of a laced wheel, providing strength and structure. We manufacture rims using high-quality materials such as aluminum alloys or stainless steel for superior impact resistance and durability. The process includes:

Material Selection: Choosing corrosion-resistant metals for longevity.

Rolling and Welding: Aluminum rims are precisely rolled and welded for a seamless structure.

Heat Treatment: Enhances strength while maintaining flexibility.

Precision Machining: Ensures a perfectly rounded profile with accurate spoke hole drilling.

3. Hub Manufacturing

The hub acts as the central connection between the wheel and the motorcycle. Our hubs are crafted from forged or CNC-machined aluminum, offering a perfect balance of lightweight strength and durability. The hub manufacturing process includes:

Forging or CNC Machining: Producing high-precision hubs with optimal weight distribution.

Bearing Seat Accuracy: Ensuring a perfect fit for smooth rotation.

Anodizing and Surface Treatment: Prevents corrosion and enhances aesthetics.

4. Spoke and Nipple Production

Spokes and nipples are crucial for structural integrity, ensuring the wheel remains strong and properly tensioned.

Spokes: Made from stainless steel or titanium, our spokes provide superior tensile strength. We offer various lacing styles, including cross-laced and radial patterns, for optimal load distribution.

Nipples: Typically made from brass or aluminum, nipples allow for fine-tuned spoke tensioning, ensuring a balanced wheel setup.

Each spoke and nipple undergoes tensile testing to confirm resistance to extreme forces and vibrations.

5. Spoke Lacing and Wheel Assembly

Our expert technicians lace each wheel by hand, ensuring precise spoke tension and alignment. Steps include:

Pattern Selection: Cross-laced or radial lacing based on the intended use.

Initial Lacing: Spokes are threaded through the hub and into the rim.

Tensioning and Truing: Each spoke is tightened to precise tension levels to achieve a true and balanced wheel.

6. Structural Integrity Testing

Every laced wheel undergoes rigorous testing to ensure reliability and safety:

Spoke Tension Testing: Verifies even tension distribution.

Trueness Testing: Ensures no wobbling or deviation.

Load and Impact Testing: Simulates extreme riding conditions.

Air-tightness Testing (for tubeless setups): Ensures an airtight seal between the rim and tire.

7. Surface Treatment and Custom Finishes

To enhance aesthetics and protection, we offer various surface treatments:

Powder Coating: Durable and vibrant color options.

Anodizing: Corrosion-resistant finish.

Polishing and Chrome Plating: High-gloss, premium look.

Custom Paintwork: Personalized styling options.

8. Branding and Personalization

Each wheel can be customized with laser-engraved logos, serial numbers, or unique identifiers based on customer preferences. This adds exclusivity and ensures traceability.

9. Final Quality Inspection

Before shipping, each wheel undergoes a thorough quality check, including:

Inspecting spoke tension and alignment.

Verifying surface finishes.

Confirming dimensional accuracy.

Ensuring all custom specifications are met.

10. Secure Packaging and Worldwide Shipping

Once quality approval is complete, wheels are securely packaged using protective materials to prevent damage during transit. Whether shipping by air, sea, or land, we ensure safe and timely delivery worldwide.

Explore Our Factory: Where Precision Meets Excellence

Take a behind-the-scenes look at how our premium laced motorcycle wheels are crafted. Every stage in our advanced facility is meticulously designed to ensure durability, strength, and top-tier performance for every wheel we produce.

What Our Customers Are Saying

Get a Quick Quote Today!

Common Questions About Our Products and Services

We manufacture wheels in a wide range of sizes to fit different motorcycles. If you have specific size requirements, feel free to mention them in the form above.

Absolutely! We produce wheels compatible with popular brands such as Harley Davidson, Yamaha, Honda, and many more. Please include your desired brand or model in your message.

Our minimum order quantity varies depending on the product and customization requirements. Contact us for more details.

We aim to respond to all inquiries within 24 hours. In some cases, it may take up to 48 hours, but rest assured, your request is our priority.

Yes, we offer assistance with shipping and customs clearance services. We provide various shipping options to suit your needs and ensure a smooth process.

Yes, customization is our specialty! We work closely with our clients to bring their designs to life. Share your ideas, and we’ll ensure your requirements are fully met.

For any additional questions or concerns, don’t hesitate to reach out to us directly. Our team is here to provide expert assistance!