Your Trusted Supplier of Premium Cast Wheels for Yamaha Scooters

High-Performance, Custom Wheels for Yamaha Xmax300 and Nmax155 – Precision Engineering for Every Ride

Yamaha Cast Wheels – The Perfect Solution for Your Business

Looking for high-quality cast wheels for Yamaha scooters? This comprehensive guide will provide you with all the essential information on sourcing premium Yamaha Xmax300 and Nmax155 wheels, along with how we can support your business with our expert manufacturing solutions.

Table of Contents

Why Choose FLEXIMOTO ?

Expertise and Uncompromising Quality

When you partner with FLEXI, you’re choosing a supplier that understands the complexity of motorcycle wheel design and production. Our team works tirelessly to create custom made cast motorcycle wheels that exceed your customers’ expectations.

Whether you need YAMAHA Scooter Cast Wheels or wheels for other brands, our wheels are crafted to ensure maximum performance and longevity on any terrain.

Our state-of-the-art casting process ensures that every wheel is created to the highest standards, with strict quality control at every step.

FLEXI specializes in custom solutions for any model or design, ensuring you have the perfect wheels for your clients’ needs.

We ship worldwide, ensuring you can serve your customers efficiently, no matter where your business is located.

Want to know how we can help your business succeed? Let’s talk!

Our Product Categories

Cast Wheels

High-performance, durable wheels for motorcycles like Harley Davidson, Yamaha, Honda, Kawasaki, Suzuki, and Vespa.

Forged Wheels

Lightweight, strong wheels for performance bikes like Harley Davidson, Indian, Yamaha, KTM, DUCATI, and BMW.

Laced Wheels

Durable wheels built for off-road motorcycles, designed for Harley Davidson, Honda, Kawasaki, Suzuki, and more.

Customization

Tailor-made wheel solutions for unique designs, sizes, and finishes, compatible with Harley Davidson, BMW, KTM, and others.

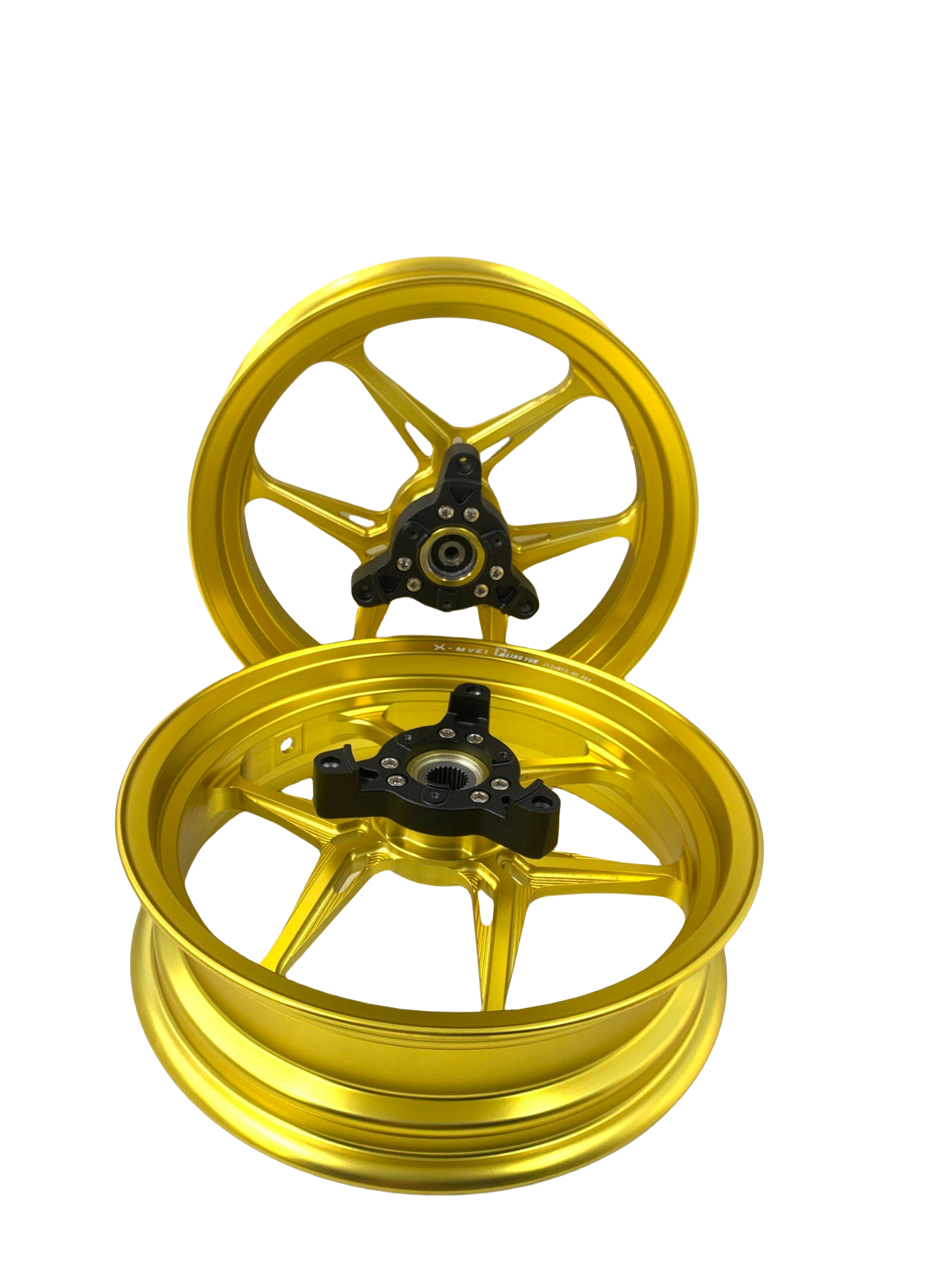

Hot Products: Yamaha Xmax300 Cast Wheels

At FLEXI Moto Wheels, we offer premium cast wheels designed specifically for the Yamaha Xmax300 scooter. Our wheels are engineered to provide the perfect balance of strength, durability, and style, making them the ideal upgrade for your business’s product offerings.

Our Xmax300 cast wheels come in a variety of custom finishes and colors to cater to different customer preferences, ensuring both aesthetic appeal and high-performance standards. Each set is crafted with attention to detail and undergoes rigorous quality checks throughout the manufacturing process.

Whether you’re targeting urban commuters or style-conscious riders, our Xmax300 cast wheels provide the performance and visual impact your customers demand, enhancing both their riding experience and your product lineup.

Hot Products: Yamaha Nmax150 Cast Wheels

FLEXI Moto Wheels brings you top-quality cast wheels designed for the Yamaha Nmax150 scooter. Built with precision and strength, these wheels are engineered for the demands of daily commuting, offering exceptional performance without sacrificing style.

Our Nmax150 cast wheels are available in a wide range of colors and finishes, allowing you to provide your customers with the flexibility to customize their ride. Every wheel set is crafted using the finest materials, ensuring long-lasting durability and a smooth ride.

As a trusted partner for B2B wholesale, FLEXI Moto Wheels guarantees superior craftsmanship and reliable delivery, making our Nmax150 cast wheels the perfect choice for expanding your product offerings and meeting the needs of your business clients.

Estimated Costs for Custom Made Cast Motorcycle Wheels

When considering custom made cast motorcycle wheels, understanding the investment is essential. The cost depends on several factors:

1)Wheel Specifications

Custom sizing, special finishes, and intricate designs may impact the final cost.

3)Finishing Options

Custom finishes, like anodizing or powder coating, add both durability and style to the wheels, affecting the pricing.

2)Material Choice

We offer a range of materials, including premium aluminum alloys, to provide the right balance of strength and weight.

4)Shipping & Import Costs

We ensure transparent pricing, including shipping fees, and will guide you through the import duties and taxes for smooth international transactions.

Estimated Manufacturing and Shipping Times for Cast Motorcycle Wheels

We prioritize efficiency and speed. With increasing customer demand for our premium cast motorcycle wheels, we’ve optimized the entire process to ensure fast and reliable delivery. Here’s an overview of the production and shipping timeline:

1. Design, Molding, and Manufacturing

The first step involves the design and creation of our cast motorcycle wheels. For new products, we will also create custom molds to ensure precise wheel shaping. After that, we select high-quality raw materials, cast them, and perform necessary machining to guarantee top-tier quality.

2. Packing and Boxing

Once the wheels are manufactured, they are securely packed in protective packaging. This ensures that each wheel is properly protected for shipping and will reach you without any damage.

3. Custom Clearance and Loading

After packing, the cast motorcycle wheels are loaded onto transport vehicles for export. The customs clearance process is handled both in the export country and the import country, ensuring a smooth transition from our facility to your destination. Our efficient logistics system helps minimize delays and optimize shipping times.

4. Sea and Land Transportation

Once the wheels arrive at the destination port, you will receive an alert. This allows you to plan how to collect your goods promptly and ensures smooth final delivery.

The Whole Process of Custom Cast Motorcycle Wheels

Here’s an overview of how we make custom cast motorcycle wheels:

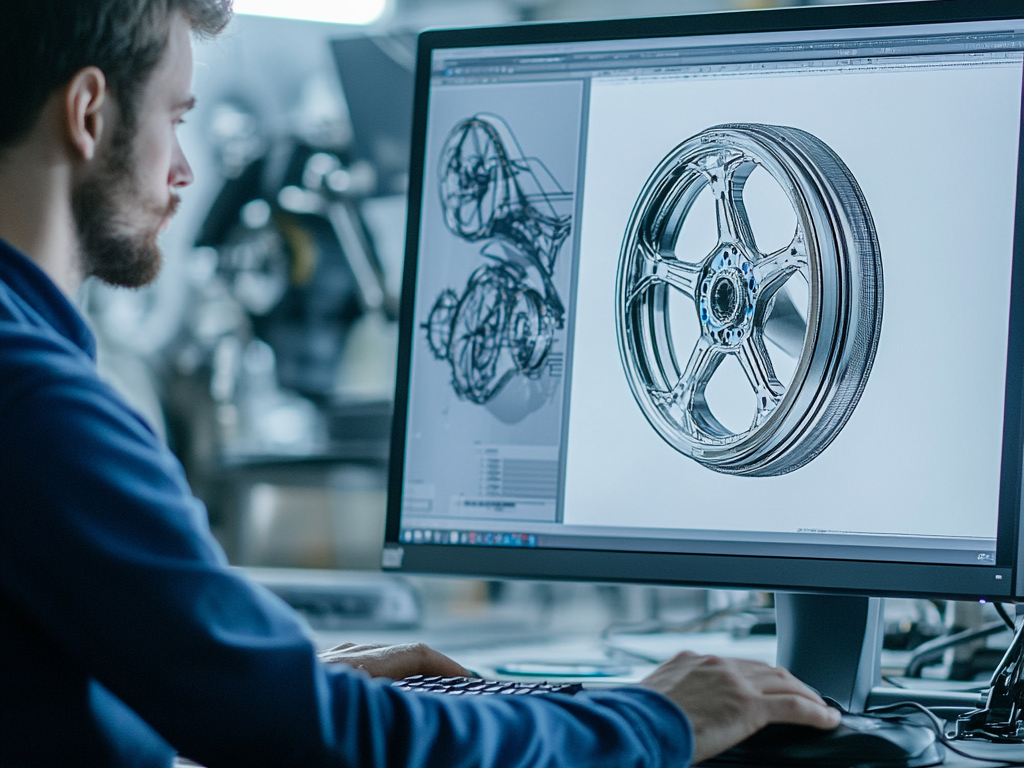

1. Design and Confirmation

We begin the process by consulting closely with our clients to understand their exact requirements. This includes gathering detailed input on aesthetic preferences, functional needs, and performance goals. Our design team then creates comprehensive blueprints, 3D models, and simulations to visualize the final product. Every aspect, from spoke design to wheel size, is carefully considered. Once the design is confirmed and approved, we ensure the final product will meet both the technical specifications and the client’s vision for their motorcycle.

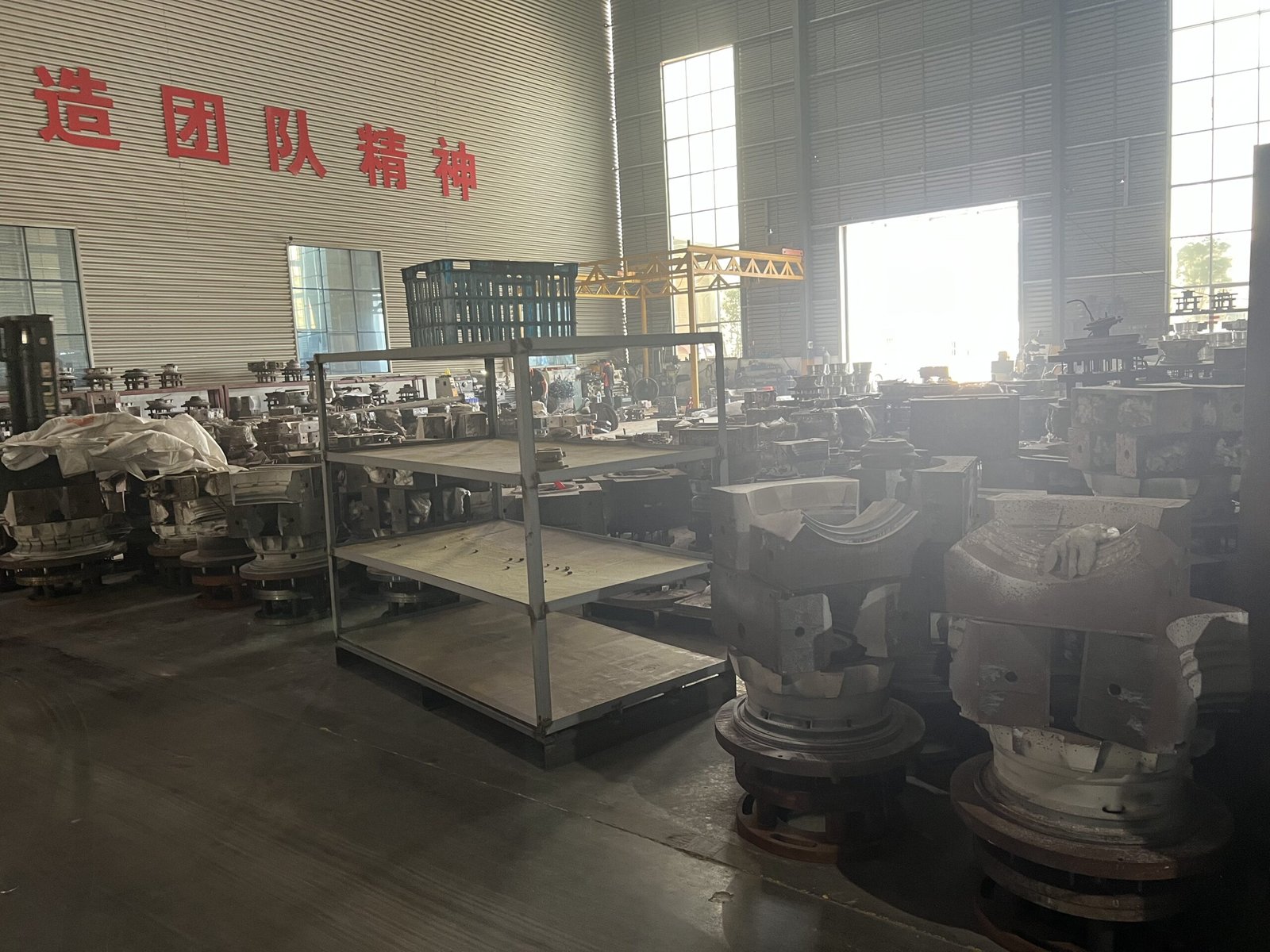

2. Mold Making

After the design phase, we move on to creating the molds that will shape the cast motorcycle wheels. This step is critical because the accuracy of the mold directly impacts the final product. We use high-grade materials that are durable and capable of withstanding the extreme temperatures of molten metal. The molds are produced with the utmost precision, ensuring that the final wheels will have the correct dimensions and surface texture. This stage also involves careful inspection of the molds for any potential imperfections that could affect the casting process.

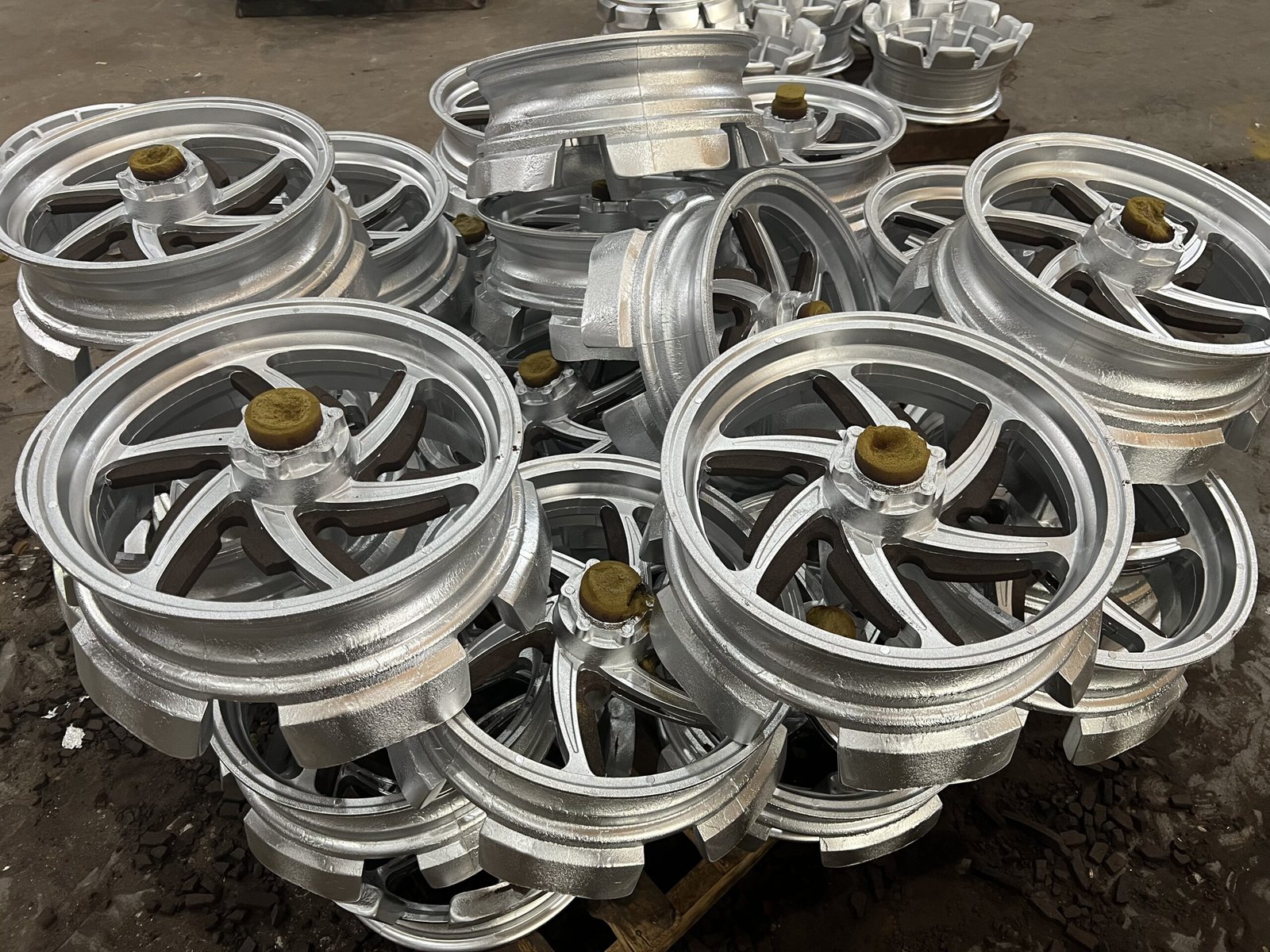

3. Casting Process

Once the molds are ready, we begin the casting process. Using gravity casting, we pour molten aluminum alloy into the mold under carefully controlled conditions. This process allows the metal to cool and solidify, forming the rough shape of the wheel. Gravity casting is chosen for its ability to produce high-quality wheels with superior strength and durability. The casting process also optimizes the metal’s grain structure, ensuring that the wheels can withstand the heavy demands placed on them by high-performance motorcycles. After cooling, the cast wheels are carefully removed from the molds, and we begin the next phase of refining them.

4. Machining (Rough and Precision)

The cast wheels are then subjected to both rough and precision machining. In the rough machining stage, we remove any excess material from the wheel and refine its shape. CNC (Computer Numerical Control) machines are used to ensure the process is accurate and efficient. In the precision machining phase, the wheels undergo finer processing to achieve the exact specifications required. This includes detailed work on spokes, hubs, and bolt holes, ensuring that every aspect of the wheel is precisely manufactured. The machining process ensures that the final product meets the highest standards of consistency, accuracy, and surface finish.

5. Leakage and Structural Testing

Each wheel is subjected to rigorous testing to ensure it meets our high standards of strength and durability. This includes air-tightness tests to ensure there are no leaks or structural weaknesses that could affect performance. We also perform pressure tests to simulate the real-world stresses that the wheels will encounter when used on motorcycles. These tests ensure that the wheels can handle the load, pressure, and vibrations typical in high-performance settings. Any wheels that do not meet the required specifications are discarded, ensuring that only the highest quality products make it to the next stages.

6. Surface Treatment and Coating

After the machining and testing phases are complete, the wheels enter the surface treatment and coating stage. This is where we enhance both the aesthetics and the durability of the wheels. Depending on the client’s preferences, we apply a variety of finishes, including powder coating, painting, chrome plating, or anodizing. These finishes not only make the wheels visually appealing but also provide additional protection against corrosion, scratches, and wear. The powder coating process, for example, creates a hard, durable finish that is resistant to chips and fading, while anodizing enhances the natural appearance of the aluminum and provides extra resistance to oxidation.

7. Marking and Engraving

Each wheel undergoes a branding and identification process to ensure traceability and exclusivity. Our logo, as well as other relevant production information, is engraved or laser-marked onto the wheel. This marking not only helps with brand recognition but also ensures that the wheel’s origin can be traced back for warranty and support purposes. The engraving is done with high precision to ensure it is clear and long-lasting, without compromising the wheel’s structural integrity.

8. Quality Control

Before the wheels are packaged and shipped, they undergo a thorough quality control inspection. Every wheel is carefully checked for balance, finish quality, and structural integrity. Our team uses advanced tools and techniques to check for any imperfections in the surface finish, alignment, or wheel strength. We also perform weight and dimensional checks to ensure that every wheel is within the required tolerances. Any wheel that does not meet our rigorous standards is rejected. Only after passing all tests and inspections are the wheels cleared for the final stage.

9. Packaging and Shipping

Once the wheels pass the final quality checks, we proceed with the packaging process. Each set of wheels is carefully packed using high-quality, protective materials to ensure they arrive at their destination in perfect condition. We use custom-designed packaging to prevent any movement during transit, reducing the risk of damage. The wheels are securely wrapped, and the packaging is clearly labeled with important information, including handling instructions and the customer’s details. Once packaged, the wheels are shipped using the most appropriate method, whether air, sea, or land transport, based on the customer’s location and delivery preferences. We ensure that each order is tracked and delivered on time, so our customers can get their products without delay.

What Our Customers Are Saying

Get a Quick Quote Today!

Common Questions About Our Products and Services

We manufacture wheels in a variety of sizes to fit different motorcycles. If you have specific size requirements, feel free to mention them in the form.

Yes, we produce wheels compatible with popular brands like Harley Davidson, Yamaha, Honda, and more. Please specify the brand or model in your requirements.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Optio, neque qui velit. Magni dolorum quidem ipsam eligendi, totam, facilis laudantium cum accusamus ullam voluptatibus commodi numquam, error, est. Ea, consequatur.

Typically, we respond within 24 hours. In some cases, it may take up to 48 hours, but we always aim to reply as quickly as possible.

Yes, if needed, we can help arrange shipping and customs clearance services. We also offer various shipping options to suit your requirements.

Yes, we can work with your design. The specific details can be discussed one-on-one to ensure your requirements are fully met.

For any other questions, please contact us directly. Our team is ready to provide personalized assistance!

01-1024x768.jpg)