Why Supply Chain Reliability Is Critical for Motorcycle Wheel Exporters

In the global motorcycle parts industry, the product matters — but the supply chain defines your reputation.

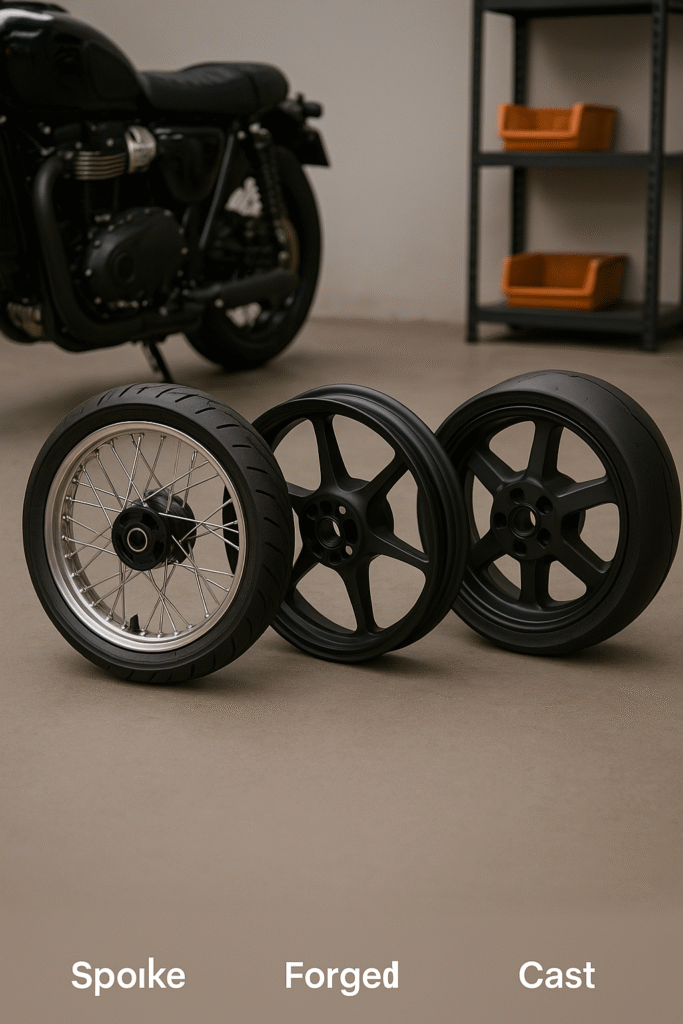

For international buyers sourcing motorcycle wheels — whether cast, forged, or laced — delays, miscommunication, or compliance issues can be the difference between profit and penalty. That’s why building a reliable, transparent, and scalable supply chain is not just good practice — it’s a competitive advantage.

In this guide, we’ll walk through key strategies and systems for creating a dependable export supply chain for motorcycle wheels, whether you’re an aftermarket brand, OEM partner, or international distributor.

Step 1: Select Suppliers with Export-Ready Infrastructure

Not every motorcycle wheel manufacturer is equipped to serve international markets. When evaluating suppliers, ensure they offer:

✅ Accurate and compliant export documentation (e.g. pro forma invoice, commercial invoice, packing list, COO, Form A/FTA, CE/ECE/DOT certificates)

✅ Experience with international freight and customs clearance

✅ ISO-certified production and QC processes

✅ Flexible MOQ and packaging customization

✅ Proven track record in Europe, North America, Asia, or Middle East

🛠️ Tip: Choose suppliers like FLEXIMOTO who offer full in-house control of production and documentation for cast, forged, and laced wheels.

Step 2: Align on Technical Specifications and Fitment Standards

One of the most common causes of shipment returns or disputes in motorcycle wheel exports is incompatibility.

Make sure your supply chain includes technical verification at multiple levels:

- Confirm hub bore, offset, bolt pattern, brake disc positioning for target models

- Align on customization codes (color, spoke layout, logo, finish)

- Use fitment charts and CAD drawings to ensure compatibility

- Ensure regional safety standards are met (ECE R75, DOT, JWL-T, etc.)

Clear pre-production alignment avoids costly post-production revisions or returns.

Step 3: Implement Multi-Checkpoint Quality Control (QC)

Export markets demand not only quality but consistency.

A reliable wheel export supply chain should include:

- Pre-production QC: raw material testing, mold inspection

- In-process QC: CNC accuracy, paint adhesion, weight tolerance

- Final QC: radial runout, dynamic balance, finishing, packaging checks

- Optional third-party inspection (SGS, Intertek, etc.)

📦 Pro Tip: Include wheel balancing test results in each shipment — it builds trust with overseas buyers and distributors.

Step 4: Standardize Packaging and Damage Prevention

Wheels are bulky, fragile, and prone to damage during transit.

Ensure your packaging system includes:

- Individual foam-lined boxes for each wheel

- Corner protection and anti-friction sleeves

- Moisture-proof sealing (especially for sea freight)

- Export carton labeling with barcode, part number, and “Made in” origin

- Palletizing plan that matches container specs (20GP, 40HQ)

Reliable packaging reduces returns, breakage, and customs inspections.

Step 5: Build a Transparent Logistics & Tracking Workflow

Buyers need more than an invoice — they want visibility.

Your wheel export chain should include:

- Shared production timelines and delay buffers

- Real-time tracking links for international air/sea shipments

- Clear HS codes, Incoterms, and insurance

- Freight forwarder cooperation with customs brokers in target countries

- Digital documentation (PDF + Excel) for faster processing

🛰️ Tip: Use collaborative tools like Trello, Notion, or simple shared folders to manage multi-party logistics.

Step 6: Plan for Scalability & Buffer Stocking

As your business grows, a reliable supply chain must scale. Build in:

- Flexible lead time frameworks (e.g. 10 days for regular orders, 20+ for custom)

- Backup production slots during peak seasons

- Forecast-based manufacturing (monthly or quarterly targets)

- Buffer stock in hub locations (especially if exporting to distributors)

For B2B partners, offering consistency > low price.

Step 7: Communicate Proactively Across Time Zones

Miscommunication is one of the top hidden costs in global supply chains.

To reduce friction:

- Assign a dedicated export coordinator

- Use shared calendars to confirm holidays across markets

- Set expectations for email response time and escalation paths

- Offer downloadable catalogs, fitment guides, and FAQ for buyers to self-serve

🤝 Case Study: One FLEXIMOTO client in Dubai cut order processing time by 40% after switching to structured communication SOPs.

Final Thoughts: Supply Chain = Sales Engine

For companies in the business of motorcycle wheels, a reliable supply chain isn’t just backend infrastructure — it’s the engine that drives customer satisfaction, cash flow, and global growth.

Invest in suppliers, systems, and processes that minimize variables — so you can scale confidently and focus on delivering performance, not excuses.

✅ Want a Supply Chain You Can Count On?

FLEXIMOTO RACING supports global B2B customers with:

- 100% in-house production (cast, forged, laced)

- Export documentation experts

- Multi-language support (EN, ES, CN)

- Experience in 40+ countries

📩 Contact us for catalogs, packing guides, and OEM terms.

Let’s build something reliable — together.