Introduction: Why Wheel Fitment is a Silent Profit Killer in the Motorcycle Industry

In the world of motorcycle customization and B2B parts supply, few issues are as underestimated — and as costly — as poor wheel fitment. While a wheel might look great in the showroom or online catalog, if it doesn’t align perfectly with the bike’s hub bore, offset, or bolt pattern, the consequences can ripple through your entire business.

From costly returns and warranty claims to long-term brand erosion and lost repeat customers, the hidden cost of poor wheel fitment is often overlooked until it’s too late. At FLEXIMOTO Wheels, we work with international buyers and custom motorcycle shops who face this problem firsthand. This article explores the risks, real-world consequences, and most importantly, how to prevent fitment issues before they damage your reputation.

1. What Exactly Is Wheel Fitment — and Why Does It Matter So Much?

Wheel fitment refers to how well a motorcycle wheel matches the dimensions and mounting characteristics of a specific motorcycle model. The core components of correct fitment include:

- Hub bore diameter

- Bolt pattern (PCD)

- Wheel offset (ET)

- Axle size and bearing compatibility

- Brake disc mounting (distance and bolt holes)

- Swingarm and fork clearance

Fitment mistakes are not just technical — they are business liabilities.

If you’re supplying wheels to custom shops in Europe, North America, or Asia, even a 2mm mismatch in offset or a misaligned bolt pattern can lead to misfitting, installation failures, and safety concerns.

2. The Real Cost of Poor Fitment: Returns, Reputation, and Revenue

🚨 A Return Is Never Just a Return

In B2B motorcycle parts export, a single returned wheel can result in:

- Double shipping costs (export and return freight)

- Customs complications or duty losses

- Unsellable product due to customized specifications

- Damaged relationships with key distributors or clients

Industry estimates suggest that every incorrectly fit wheel can cost $300–$600 in logistics and administration alone — not including opportunity loss.

⚠️ Warranty Claims & Legal Exposure

If a misfitted wheel causes:

- Brake system misalignment

- Chain or sprocket offset issues

- Frame interference

…it can lead to dangerous ride conditions. In North America or the EU, this can trigger warranty disputes or even legal liability — especially if no fitment documentation was provided.

💔 Brand Trust Takes a Hit

The most dangerous cost is often invisible: loss of trust.

Distributors may stop ordering. Custom shops may post about their experience online. In today’s global B2B landscape, your brand is only as strong as your quality control.

3. Common Causes of Fitment Errors in the B2B Supply Chain

- Inaccurate CAD files or misused templates

- Assuming cross-compatibility between brands (e.g., Yamaha MT vs R series)

- Lack of fitment verification before shipment

- Failure to communicate precise axle, disc, or sprocket specs

- Disregarding regional variant models (e.g., EU vs USA Harley-Davidson frames)

4. Fitment Gone Wrong: Real-World Examples

🇸🇪 Case: Swedish Custom Shop Receives Misfit Rear Wheel

A customer in Sweden ordered a custom forged rear wheel for a Harley-Davidson Softail. The wheel’s hub bore and axle diameter were based on outdated spec sheets from the 2021 model. Upon installation, the rear axle wouldn’t fit. The shop missed a deadline for their customer’s show bike. FLEXIMOTO later helped resolve the issue, but not before the shop considered switching suppliers.

🇦🇺 Case: Returns from Australia Due to Bolt Pattern Error

An Australian wholesaler returned an entire shipment of laced wheels due to a 5×112 bolt pattern shipped instead of 5×120 — a factory mismatch due to template confusion. It cost the supplier over $5,000 in freight and restocking fees.

5. How to Prevent Fitment Failures — Best Practices from Industry Leaders

✅ 1. Always Use a Fitment Chart and Require Client Confirmation

Ask clients to sign off on wheel specs before production. A well-designed Wheel Fitment Chart (PDF or online form) minimizes disputes.

✅ 2. Match Wheels to OEM Specifications

Use verified OEM specs for every model. Cross-check with platforms like Partzilla or Fiche Finder.

✅ 3. Offer Fitment Simulation via CAD or 3D Tools

Advanced suppliers use CAD models to simulate hub, disc, and axle positions. This catches issues before the wheel is cut.

✅ 4. Special Attention to Brake Compatibility

Use templates or jigs that test brake rotor clearance. Especially for dual-disc front ends, any misalignment is dangerous.

✅ 5. Educate Your Customers on Fitment Basics

Provide a basic guide like: How to Measure Wheel Offset and Hub Bore (Motorcycle Cruiser)

6. FLEXIMOTO’s Fitment Guarantee: Precision That Builds Trust

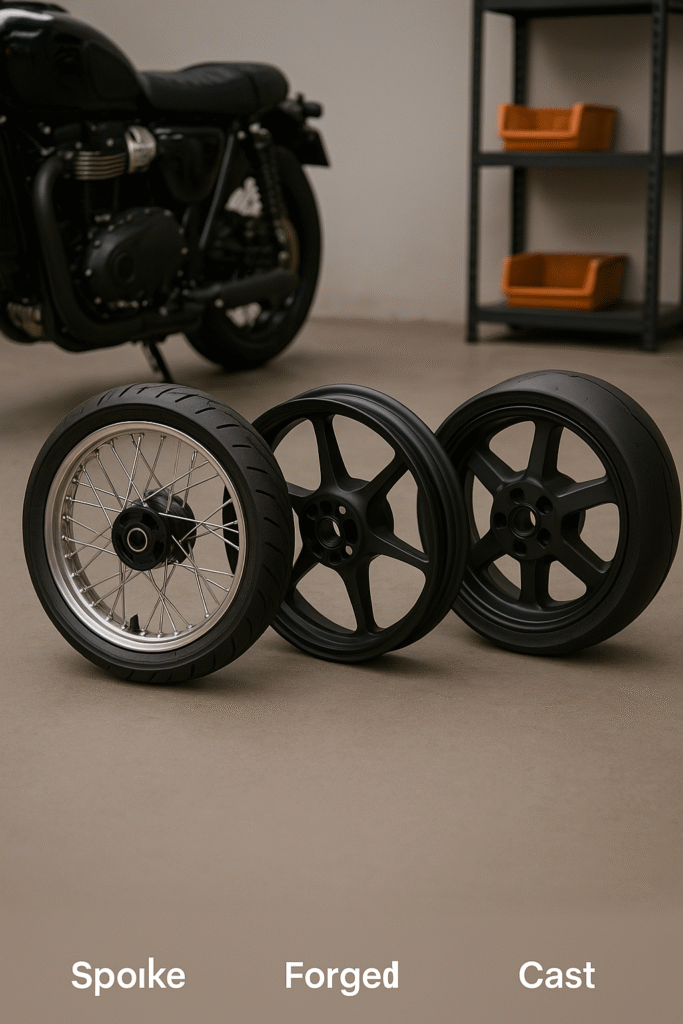

At FLEXIMOTO, we export cast, forged, and laced motorcycle wheels with exacting fitment support. Our process includes:

- CAD-verified designs

- Multi-step QC for all hub/bolt specs

- Custom fitment charts for each client

- Compatibility confirmation for over 300 motorcycle models

- ECE/DOT certification documentation for customs compliance

Whether you’re customizing a Triumph in Germany or building track bikes in Canada, FLEXIMOTO ensures your wheels fit right — the first time.

Conclusion: Fitment Isn’t Just Technical — It’s Strategic

Poor fitment isn’t just an inconvenience. It’s a direct hit to your profit, brand, and operational trust. As B2B motorcycle part buyers become more global and demanding, precision becomes your most valuable asset.

If you’re a procurement professional, custom builder, or international dealer — don’t gamble on specs.

📩 Contact FLEXIMOTO today for custom wheels with guaranteed fitment and documentation support for global shipping.