TL;DR

- Forged wheels are usually lighter and stronger per kilogram, but cost more and require tighter engineering control.

- Cast wheels are typically the most cost-effective for scalable programs, but are often heavier and more sensitive to process consistency.

- For B2B sourcing, the biggest risks are fitment repeatability, runout, finish tolerance, documentation gaps, and warranty claims.

- The right choice depends on your market position, target margin, order volume, and import expectations.

1. Why This Matters for B2B Buyers

If you are sourcing wheels for wholesale, OEM supply, or custom builds, the forged vs cast decision affects total cost of ownership more than most buyers expect. The pain usually shows up later as claims, delays, or fitment problems, not on the first sample.

Key B2B pain points:

- Returns and warranty exposure from cracking, runout, or installation issues

- Batch-to-batch repeatability for PCD, offset, hub bore, brake alignment, and ABS interfaces

- Import readiness for EU, UK, US, AU, and Middle East buyers who demand accurate documentation and traceability

- Lead time risk from tooling, sampling loops, and slow approvals

- Reputation risk when one failed batch impacts your shop reviews or distributor relationships

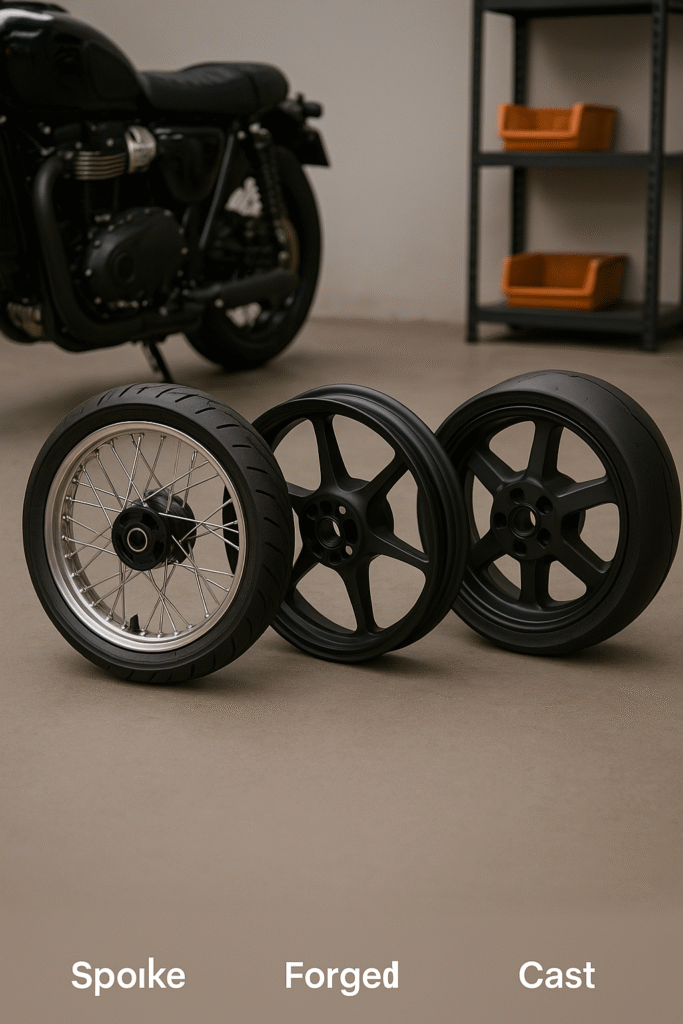

2. Core Concepts Explained

What Cast Motorcycle Wheels Are

Cast wheels are made by pouring molten aluminum alloy into a mold, letting it cool, then machining critical areas such as bearing seats, rotor mounts, and bead seats. Common methods include gravity casting and low-pressure casting.

What this means in practice:

- Efficient for higher-volume production and competitive pricing

- Casting can introduce micro-porosity or density variation if process control is weak

- Many cast designs use thicker sections to hit strength targets, which increases weight

What Forged Motorcycle Wheels Are

Forged wheels start from a solid aluminum billet or preform that is heated and pressed under very high pressure, then CNC-machined to final geometry. Forging typically produces a denser structure and more consistent mechanical properties.

What this means in practice:

- Higher strength-to-weight ratio

- Typically lower porosity compared with casting

- Allows thinner cross-sections, enabling meaningful weight reduction

Common Misunderstandings Buyers Should Avoid

- Forged does not automatically mean perfect. Design, heat treatment, tolerances, and QC define real performance.

- Flow-formed or rotary-forged is not the same as fully forged. Confirm the exact process.

- Stronger and more impact tolerant are not identical. Real-world durability depends on geometry, alloy, heat treatment, and inspection control.

3. Technical Breakdown and Comparison

Side-by-Side Comparison Table

| Attribute | Forged Wheels | Cast Wheels |

|---|---|---|

| Manufacturing | High-pressure forming from billet or preform plus CNC machining | Molten alloy poured into mold plus machining |

| Typical Weight | Often 15 to 30 percent lighter, depending on design | Often heavier due to thicker sections for strength |

| Strength-to-Weight | Excellent | Good, typically lower than forged |

| Porosity Risk | Lower relative risk | Higher relative risk, depends on casting control |

| Dimensional Repeatability | High due to CNC-driven geometry | Good to moderate, mold condition and process variation matter |

| Impact Behavior | Often better deformation tolerance for the same weight | Can crack under severe impact if pushed beyond design limits |

| Styling Options | Premium machined finishes common | Wide variety of styles and finishes |

| Best Fit | Premium performance builds, high-end custom programs | Value SKUs, mainstream street and touring, OEM-style volume |

| Unit Cost | Higher | Lower |

Why Weight Matters in Real Use

Lower wheel weight reduces unsprung mass and rotating mass:

- Suspension can respond faster to road irregularities

- Acceleration and braking feel more immediate

- Direction changes require less effort, most noticeable in sport and track segments

4. What B2B Buyers Should Pay Attention To

MOQ

- Cast programs often tie MOQ to mold economics and finishing batch efficiency

- Forged programs can sometimes support lower MOQs, but CNC time and validation can raise practical MOQ

Buyer tip: Confirm MOQ by fitment and finish, not only by model name.

Tooling and Development

- Cast typically requires molds and sometimes variant tooling

- Forged often requires forging dies, fixtures, and more CNC programming

Buyer tip: Tooling is also a schedule risk if revisions occur late.

Lead Time

Real lead time includes:

- Spec confirmation

- Prototype and sample

- Fitment validation

- Finish approval

- Pre-production

- Mass production

Buyer tip: Approval speed and revision count often matter more than the wheel type.

Documentation and Import Readiness

International buyers commonly request:

- 2D drawings and key tolerances

- Material and heat-treatment notes

- Runout and balance targets

- Traceability such as batch marking and QC records

- Test documentation when required by customer or market

Buyer tip: Documentation is part of the product in B2B trade.

Risk Points

- Fitment mismatch for offset, PCD, hub bore, rotor alignment, ABS interfaces

- Excessive runout or poor balance control

- Finish thickness affecting bolt seating, bead seat, or hub interfaces

- Packaging damage in export logistics

- Inconsistent output across batches due to uncontrolled subcontracting

5. Real-World Application Scenarios

When Forged Wheels Make Sense

- Premium custom shops selling high-ticket builds

- Track-day and performance-focused customer bases

- Weight-sensitive projects where handling improvements are a key selling point

- Brands that need differentiation beyond appearance

When forged may not be ideal:

- Channels where price is the main decision driver and customers will not pay for weight savings

When Cast Wheels Make Sense

- Price-competitive wholesale programs

- OEM-style replacement and mainstream street segments

- High-volume SKUs with stable specs and fewer variants

When cast may not be ideal:

- Thin, aggressive designs that push casting limits while still aiming for premium performance claims

A Common Failure Pattern

A distributor launches a premium-looking cast wheel with very thin spokes to mimic forged aesthetics. Early sales are strong, but claims rise after pothole-heavy seasons. Root cause is stress concentration in thin transitions combined with inconsistent casting density control.

Lesson: If the design demands thin sections and premium performance positioning, forging or a conservative redesign with strict QC becomes necessary.

6. Common Mistakes to Avoid

- Mistake 1: Buying by the process label instead of measurable specs

Require runout targets, load expectations, and inspection checkpoints. - Mistake 2: Underestimating fitment complexity

Offset, rotor alignment, and ABS interfaces cause most expensive problems. - Mistake 3: Approving finishes without functional validation

Always validate the final finished part, not only raw machined samples.

7. How We Handle This at FlexiMoto Wheels

At FlexiMoto Wheels, we treat forged vs cast as a sourcing system decision focused on export repeatability and risk control.

What we typically support for B2B projects:

- Engineering review before sampling: size, width, PCD, offset, hub bore, brake and ABS interfaces, load targets

- DFM feedback to reduce stress concentrators and improve manufacturability

- QC control points: machining tolerance checks, runout and balance targets, finish inspection standards

- Documentation support aligned to project needs: drawings, key dimension reports, traceability records

- Customization capability: finishes, colors, branding, and model-specific fitment development

FAQ

Q1: Are forged motorcycle wheels always better than cast wheels?

A: Not always. Forged wheels typically offer better strength-to-weight and lower porosity, but the best choice depends on price targets, volume, positioning, and risk tolerance. Design and QC matter for both.

Q2: How much lighter are forged wheels compared to cast wheels?

A: Many forged wheels are roughly 15 to 30 percent lighter than comparable cast wheels, depending on size and design.

Q3: Why do forged wheels cost more?

A: Forging requires specialized equipment, dies and fixtures, and often more CNC machining time. Development and validation for custom programs can also add cost.

Call to Action

Looking for a reliable partner for custom forged motorcycle wheels or export-ready cast wheel programs

Send your specs size, PCD, offset, finish, quantity, and our engineering team will review feasibility within 24 to 48 hours.

Contact Us Now.