A lot of wheels are marketed as “forged,” but not all forged claims are equal. For a custom shop or distributor, the difference isn’t academic: it shows up in fatigue life, impact tolerance, weight targets, and—just as importantly—documentation you can trust when you import and resell.

This guide breaks down what a “true forged” motorcycle wheel really means, how to verify it with supplier evidence, and how to avoid common “forged-ish” marketing traps—so you can source with confidence and fewer surprises.

The short definition of a “true forged” wheel

A true forged motorcycle wheel starts as a forged aluminum preform (not molten metal poured into a mold), shaped under high pressure—typically via closed-die forging—and then precision-machined to final dimensions. Closed-die forging forces metal into a die cavity and controls material flow, enabling high integrity structures.

Why that matters: forging can orient and refine the internal grain structure (“grain flow”) around the part shape, improving resistance to impact and cyclic fatigue compared with many non-forged routes.

A buyer’s checklist: 6 signs you’re looking at “true forged”

Use this as a fast filter before you even ask for a quote:

- Manufacturing route is explicit: “closed-die forged” (or “impression-die forged”) center, not vague “forged technology.”

- A forged preform exists: supplier can show preform photos/video and die/tooling references.

- Material and temper are specified: e.g., 6061-T6 or 7075-T6 (or equivalent) with traceability.

- Heat treatment is documented: solution + aging steps, hardness range, and QC checkpoints.

- Testing evidence is available: radial fatigue, cornering fatigue, torsion fatigue, impact test—ideally aligned to recognized methods such as ISO 8644 or JASO T 203-85.

- Dimensional control is proven: runout targets, balancing process, and fitment drawings.

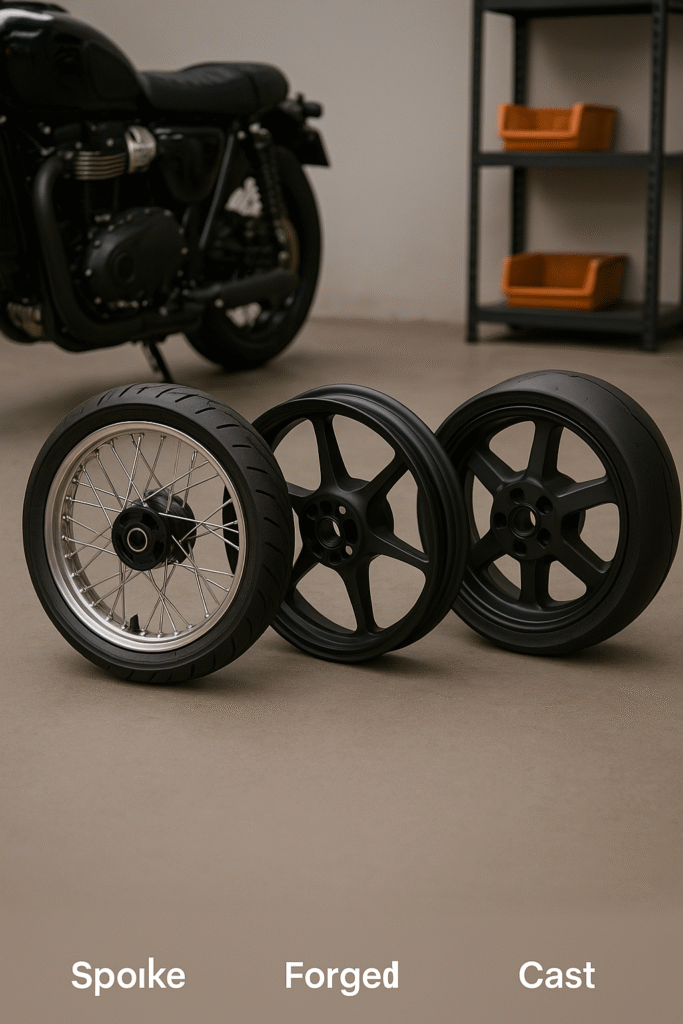

Forged vs cast vs flow-formed: what’s different (and what isn’t)

Many sourcing mistakes happen because “forged” gets used as a vibe, not a process.

| Manufacturing route | What it usually means | Typical strength-to-weight potential | Common risk if oversold |

|---|---|---|---|

| Cast | Molten metal poured into a mold | Medium | Porosity/defects depending on process & QC |

| Flow-formed / flow-forged (rim/barrel only) | Center often cast + barrel strengthened by forming | Medium-High | Marketed as “fully forged” when it isn’t |

| True forged (closed-die forged preform) | Forged blank shaped under pressure + CNC | High | Higher tooling cost; supplier must prove process |

If a supplier says “flow forged” but implies the whole wheel is forged, treat it as partially forged unless they provide clear evidence.

How a true forged motorcycle wheel is made (step-by-step)

1) Alloy selection and billet preparation

A true forged route starts with a controlled alloy (commonly 6061 or 7075 families). Your goal is consistency and traceability, not just a marketing grade name.

2) Heating and closed-die forging

In closed-die forging, the heated metal is forced into a die cavity, controlling flow and shaping the preform efficiently.

This step is where the wheel’s internal structure can become more favorable for high-stress use, with grain flow aligned to the part geometry.

3) Trimming, pre-machining, and stress management

Excess material is removed and key surfaces are prepared. A good supplier will control deformation and stress before final CNC.

4) Heat treatment (temper matters)

Many forged wheels rely on T6 temper for the final balance of strength and toughness. Ask what temper is used and how it’s verified (hardness checks, batch records).

5) Precision CNC machining

CNC defines the real-world fit: hub bore, bolt pattern, offset, spoke geometry, bead seat, and runout.

6) Surface finishing and corrosion protection

Typical options: anodizing, powder coating, painting, or multi-step show finishes. Finishing should be treated as a controlled process, not just cosmetics.

7) QC + testing

Beyond dimensional QC, credible suppliers can reference test methods aligned to standards such as ISO 8644 (motorcycle light-alloy wheel test method—note ISO has newer editions) and/or JASO T 203-85, which includes multiple wheel tests like fatigue and impact.

6061-T6 vs 7075-T6: what those grades actually signal

These alloys are often discussed as shorthand for performance potential. Here are typical mechanical property references from ASM/MatWeb (values vary by product form and processing):

| Alloy temper | Typical ultimate tensile strength | Typical yield strength |

|---|---|---|

| 6061-T6 | ~310 MPa | ~276 MPa |

| 7075-T6 | ~572 MPa | ~503 MPa |

How to use this in procurement (practical take):

- Treat alloy/temper as a starting point, not the whole story. Process control, heat treat verification, and testing matter just as much.

- Ask for material certs, temper confirmation, and batch traceability to avoid “label-only” specs.

Proof you can request from any supplier (copy/paste list)

If a vendor claims “true forged,” these are reasonable asks for B2B buyers:

- Process statement: closed-die forged preform + CNC machining (with photos of forging stage)

- Material certificate: alloy grade, heat number, traceability

- Heat treatment records: temper targets, hardness checks

- Dimensional QC: runout, offset tolerance, hub bore tolerance, bolt pattern verification

- Test reports: fatigue + impact testing aligned to ISO/JASO methods when applicable

- Export documentation readiness: packing list, commercial invoice accuracy, HS code support, COO when needed

Common “forged” marketing traps (and how to respond)

“Forged look” / “forged style”

That’s aesthetics, not metallurgy. Ask for the manufacturing route and the forged preform evidence.

“CNC from billet = forged”

CNC from bar/plate is not the same as closed-die forging. Grain flow benefits are not identical when you simply machine a shape out of stock.

“Flow forged = fully forged”

Flow-formed barrels can be a legitimate upgrade, but it’s not automatically “fully forged.” Require clarity on what portion is forged.

How FLEXIMOTO supports true-forged sourcing (B2B reality)

FLEXIMOTO Wheels LLC (FLEXIMOTO RACING) is built around B2B export + OEM/wholesale customization, with wheel categories covering forged, cast, and laced—so buyers can match performance targets, price points, and market positioning.

What this means for procurement teams and custom shops:

- Customization-ready: sizes, finishes, branding/marking, and fitment alignment for your build list

- Documentation discipline: structured specs + export paperwork accuracy (critical for EU/UK and other regulated import workflows)

- Scalable supply: wholesale/OEM processes designed for repeat orders, not one-off hobby shipments

FAQ (for buyers who need to decide fast)

Is “true forged” always the best choice?

Not always. If your market is price-sensitive or the use case is mild, a high-quality cast wheel may be the better business decision. True forged shines when weight, fatigue life, and premium positioning matter.

What’s the fastest way to verify “true forged”?

Ask for forging-stage evidence + material/temper proof + test alignment (ISO/JASO method references).

What testing should I care about most?

For street and performance use, fatigue durability and impact resistance are common priorities; ISO/JASO-aligned methods provide a familiar language across suppliers and markets.

Conclusion: “True forged” is a process you can audit, not a label you must trust

A true forged motorcycle wheel is defined by a verifiable manufacturing route (forged preform + controlled heat treat + CNC), backed by evidence—material traceability, QC, and credible testing references. When you source with that mindset, you reduce warranty risk, protect your brand reputation, and build a supply chain you can scale.

CTA (for B2B buyers)

If you’re sourcing true forged wheels for wholesale, OEM, or custom-shop builds, send us:

- target models + wheel sizes

- desired finishes + branding

- estimated order volume + destination country

FLEXIMOTO will respond with a fitment/spec checklist, recommended process route (cast/forged/laced), and an export-ready quotation package.