Buying wheels in bulk isn’t just about style. For B2B buyers, the wrong wheel type can lead to fitment disputes, returns, and delays. This guide helps you choose between forged, cast, and laced (spoked) wheels using three filters: application, budget, and strength-to-weight.

Watch the video version:

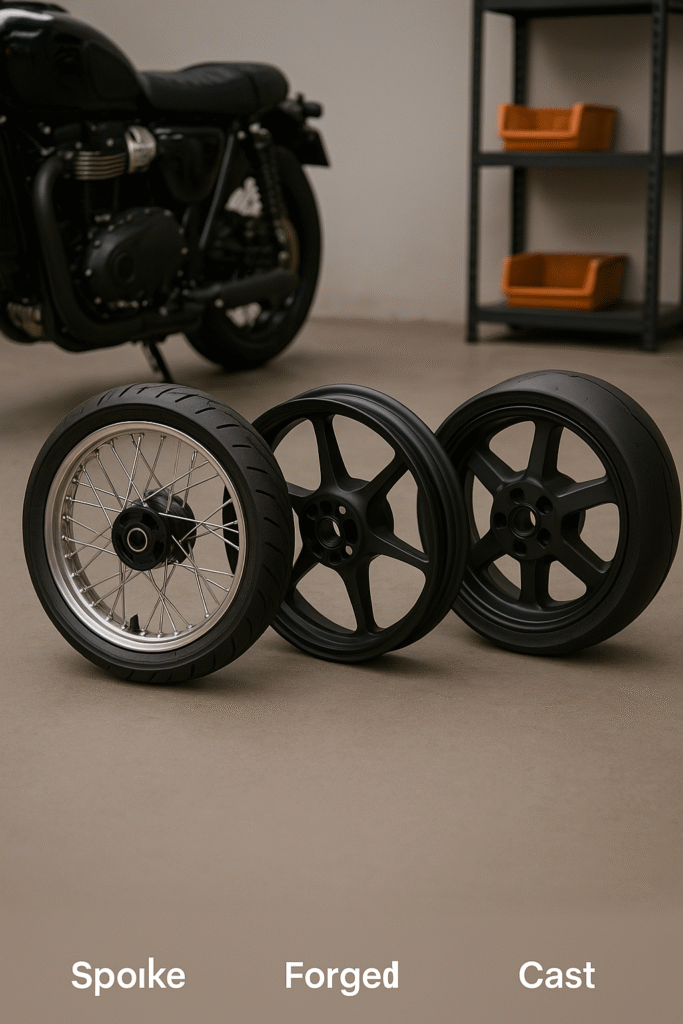

Quick answer

- Forged wheels → best for cruisers & performance when strength-to-weight and premium finishes matter.

- Cast wheels → best for scooters & standard use when cost efficiency and stable supply matter.

- Laced (spoked) wheels → best for off-road/adventure when impact durability and serviceability matter.

What’s the real difference?

Forged wheels

Best for: Cruiser / Performance street

Why buyers choose it: strong strength-to-weight, better fatigue resistance, premium finishes

Watch-outs: higher cost; fitment confirmation is critical (offset, rotor interface, ABS ring)

Cast wheels

Best for: Scooter / Commuter / value lines

Why buyers choose it: best cost efficiency and repeatable production

Watch-outs: often heavier than forged; less ideal for extreme performance use

Laced (spoked) wheels

Best for: Off-road / Adventure

Why buyers choose it: impact survivability, serviceable (spokes replaceable, wheel truing)

Watch-outs: maintenance expectations; tubed vs tubeless depends on rim design; QC should check spoke tension + runout

Choose by application (fast map)

- Cruiser / Touring: Forged (premium) or Cast (value)

- Scooter / Urban: Cast

- Performance street: Forged

- Off-road / Adventure: Laced

Choose by budget (total landed cost)

Don’t judge by unit price only. Consider:

packaging + shipping + duties + return risk + shop labor time.

One return shipment can erase the “savings” of choosing cheaper wheels.

Biggest mistake: “Same size means it fits”

Size alone doesn’t guarantee fitment. Confirm:

offset, bolt pattern (PCD), center bore, rotor interface, ABS ring, sprocket/pulley interface.

B2B Fitment & Spec Checklist (copy/paste)

Bike info

- Brand / Model / Year:

- Front wheel size:

- Rear wheel size:

- ABS: Yes/No:

- Rotor size / disc setup:

Wheel specs

- Rim size & width (front/rear):

- Bolt pattern / PCD:

- Offset (ET):

- Center bore:

- Axle diameter:

- Rotor mounting interface:

- ABS ring interface (if applicable):

- Sprocket/pulley interface (chain/belt):

Commercial

- Finish & color:

- Quantity:

- Destination city/port:

- Required documents:

Get a recommendation + quote

Send your bike model, riding use, and target weight—our engineers will recommend the best option and quote.

👉 https://fleximotowheels.com/contact/

Want more guides like this? Subscribe on YouTube https://youtu.be/rBx56pSG6xQ.