Choosing wheel material isn’t just a “lighter is better” decision—especially for B2B buyers who need repeatable quality, stable supply, accurate documentation, and predictable performance across different riding styles and markets.

In the aftermarket and OEM world, you’ll see three materials come up again and again:

- 6061-T6 aluminum

- 7075 (often 7075-T6) aluminum

- Magnesium alloys (common in racing applications)

This guide breaks down strength, weight, fatigue life, corrosion behavior, manufacturability, cost, and real-world fit—so procurement teams and custom shops can choose the right option for each build.

Quick Takeaways (if you’re deciding fast)

- Best all-round choice (value + durability + supply stability): 6061-T6

- Best high-performance aluminum option (strength/rigidity): 7075-T6

- Best for maximum weight savings (track-focused): Magnesium — but higher cost and higher care requirements

What “Best” Actually Means for Motorcycle Wheels

For wheels, “best material” depends on your priorities:

- Strength & stiffness (handling precision, brake feel, load capacity)

- Fatigue resistance (long-term crack resistance under cyclic stress)

- Impact behavior (potholes, curbs, off-road hits)

- Corrosion resistance (road salt, coastal climates)

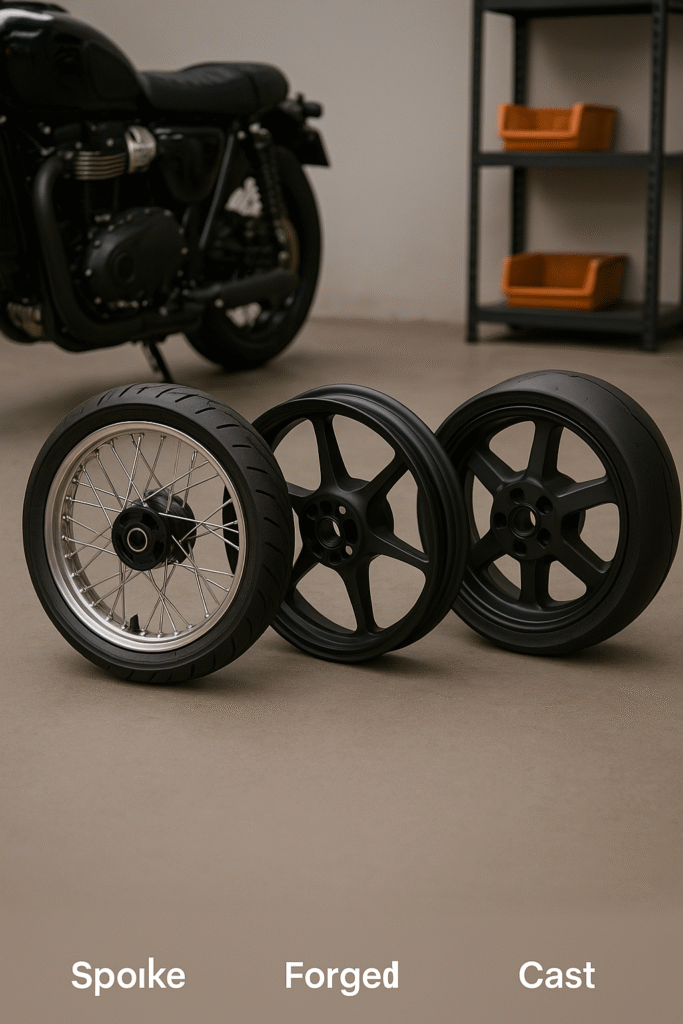

- Manufacturing route (forged vs cast, machining time, scrap rate)

- Total landed cost (not just part price—QC, rejection rate, warranty risk)

- Compliance & documentation (traceability, material certs, inspection records)

Material 1: 6061-T6 Aluminum (The Workhorse)

What it is

6061 is a widely used aluminum alloy known for excellent corrosion resistance, weldability, and stable mechanical properties. “T6” refers to solution heat treatment + artificial aging, improving strength.

Why it’s popular for wheels

- Reliable in production (good consistency batch-to-batch)

- Easier to machine than higher-strength alloys

- Strong enough for most street and mixed-use wheel designs

- Great corrosion resistance for export markets (EU coastal areas, winter roads)

Best fit for

- Street / cruiser / touring

- Daily riders

- B2B programs needing predictable lead times and low warranty risk

- Forged or high-quality cast designs where geometry does the heavy lifting

Watch-outs

- If you’re chasing peak stiffness or ultra-thin spokes, 6061 can require more material than 7075 to reach the same rigidity.

Material 2: 7075-T6 Aluminum (High-Strength, Performance-First)

What it is

7075 is a zinc-alloyed aluminum known for very high strength and stiffness. In wheel applications, it’s often chosen when designers want lighter sections without losing rigidity.

Why builders choose 7075

- Higher strength enables thinner profiles (when design + process are controlled)

- Improved stiffness can translate to sharper handling and better feedback

- Ideal for premium forged wheel programs

Best fit for

- Performance street builds

- Track-day and sportbike applications

- High-end custom shops marketing “lightweight forged” upgrades

- Programs where engineering control (forging + heat treat + QC) is strong

Watch-outs (important for buyers)

- Typically more expensive and can be less forgiving if the design/process is poorly controlled.

- Corrosion resistance is generally not as friendly as 6061, so coatings and surface treatment matter more.

Material 3: Magnesium Alloys (The Lightweight King—With Tradeoffs)

What it is

Magnesium wheels are used in racing because magnesium has very low density (lighter than aluminum). Common wheel alloys vary by manufacturer, but the theme is the same: maximum weight savings.

Why racers love it

- Biggest reduction in unsprung mass

- Faster acceleration/deceleration feel

- Quicker turn-in and improved suspension response

Best fit for

- Track-only or race-focused builds

- Teams and shops that can manage strict inspection and maintenance

- Customers who understand magnesium’s lifecycle and care needs

Watch-outs (where many buyers get burned)

- Corrosion risk is significantly higher—coatings are non-negotiable.

- More sensitive to surface damage (chips/scratches can start corrosion).

- Often higher inspection requirements and shorter service expectations in hard use.

- Higher cost + higher risk in warranty-heavy markets.

Side-by-Side Comparison

| Criteria | 6061-T6 Aluminum | 7075-T6 Aluminum | Magnesium Alloy |

|---|---|---|---|

| Density / Weight | Medium | Medium | Lowest |

| Strength / Stiffness | Good | Very high | Varies (often good, but depends on alloy & process) |

| Fatigue Behavior | Strong in well-designed wheels | Strong but needs tighter control | Sensitive; requires strong QC + maintenance |

| Corrosion Resistance | Excellent | Good–medium (coatings matter) | Challenging (coatings essential) |

| Manufacturability | Easiest (machining, availability) | Harder/more costly | Specialized |

| Cost (material + process) | Best value | Higher | Highest |

| Best Use | Street, touring, mixed | Performance street/track-day | Track/racing focus |

The Missing Piece: Manufacturing Process Matters as Much as Material

Two wheels labeled “7075” can perform very differently based on:

- Forging vs casting

- Heat treatment control (true T6 cycle, consistency)

- Grain structure (forged advantages)

- Machining strategy (stress risers, surface finish, radii)

- QC methods (runout, X-ray/NDI policies, hardness checks, dimensional inspection)

Rule of thumb for buyers:

A well-designed forged 6061 wheel from a disciplined manufacturer can outperform a poorly controlled 7075 wheel in real life.

How to Choose the Right Material (By Customer Type)

If your buyers are street + touring (and you need low claims)

Pick 6061-T6.

It’s stable, corrosion-resistant, and easier to support with consistent production quality.

If your buyers are performance enthusiasts (and you sell “premium feel”)

Pick 7075-T6, ideally forged, with strong process documentation (heat treat records + inspection checkpoints).

If your buyers are racers (and you can manage the risk)

Pick magnesium, but set expectations:

- strict coating care

- inspection intervals

- intended use (track vs street)

- clear warranty boundaries

Procurement Checklist: What to Ask Your Wheel Supplier

When you’re sourcing internationally, material claims should be backed by documentation and process control. Ask for:

- Material certificates (per batch/heat)

- Heat treatment verification (T6 documentation)

- Hardness test results (spot checks across production)

- Runout and balance standards

- Surface treatment specs (anodizing, powder coat, conversion coating)

- Traceability (serial/batch ID tied to QC records)

- Packaging standards for export (to prevent coating damage in transit)

If a supplier can’t provide these, the alloy choice won’t save you from returns.

FAQs

Is 7075 always better than 6061 for wheels?

Not always. 7075 has higher strength, but the wheel design and manufacturing control often matter more than the alloy name.

Are magnesium wheels safe for street use?

They can be, but they demand excellent coating protection and more attention to inspection and damage. Many programs treat them as race-focused for good reasons.

Which material is best for custom shops selling internationally?

For most B2B export programs: 6061-T6 forged or high-quality cast offers the best balance of cost, durability, and corrosion performance. 7075 is excellent for premium tiers.

Bottom Line

- Choose 6061-T6 when you want reliable durability, corrosion resistance, and scalable production.

- Choose 7075-T6 when you want maximum stiffness/strength in a premium performance wheel, and your supplier has strong QC.

- Choose magnesium when the goal is absolute weight reduction, and the customer understands the care, inspection, and cost.

If you want, I can also tailor a recommended material mix by your target market (EU winter roads vs Australia coastal vs Middle East heat) and by bike segment (Harley touring vs ADV vs sportbike).