Introduction

In today’s highly competitive global motorcycle parts market, custom mold development has become a cornerstone of quality, performance, and differentiation — especially for OEMs and aftermarket wheel exporters targeting Europe, North America, Australia, and the Middle East. For procurement professionals and shop owners sourcing custom motorcycle wheels, understanding the entire mold development process — from design to lead times — is crucial to manage expectations, reduce risk, and improve supply chain predictability.

This article breaks down industry best practices, explains key process steps, clarifies common lead‑time variables, and shares actionable insights that help you avoid costly delays or miscommunication with suppliers.

Why Custom Molds Matter in Motorcycle Wheel Manufacturing

Before we dive into the details, it’s important to understand what a mold is and why it matters:

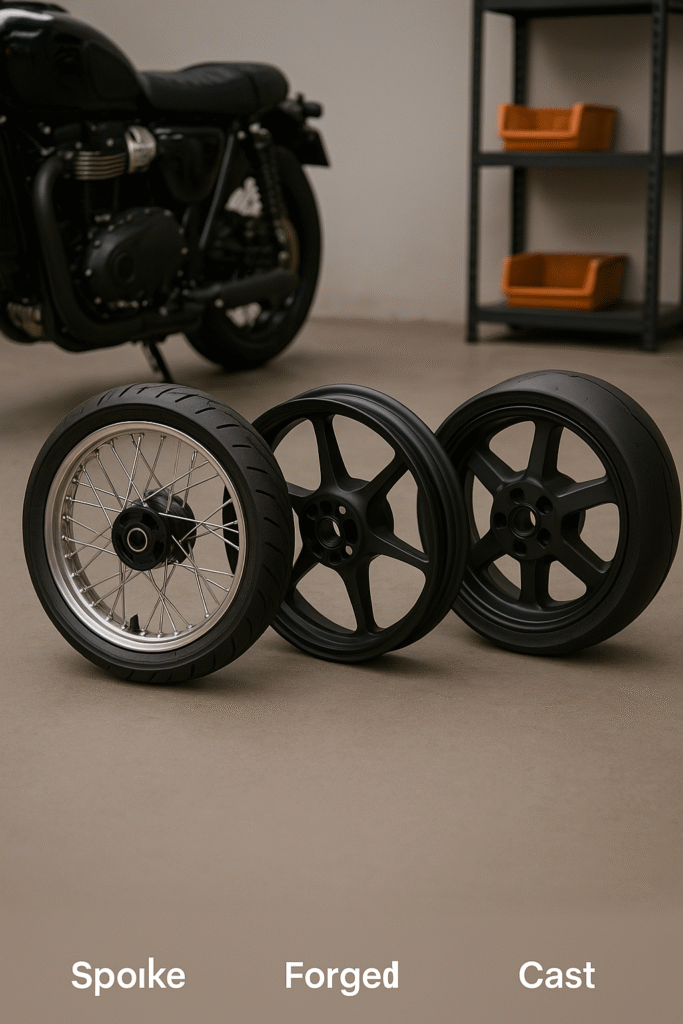

A mold defines the exact shape, geometry, dimensions, and structural features of a wheel. It is the blueprint in physical form that guides how molten metal flows and solidifies (in casting) or how material is formed under pressure (in forging) to become a finished wheel. Without a precise mold, wheels can suffer from quality issues such as dimensional inconsistencies, imbalance, poor fitment, or structural weakness — all of which affect safety and performance. metamold.com

Leading custom wheel suppliers around the world may maintain hundreds to thousands of wheel molds across different sizes and designs, reflecting ongoing product development and market diversification. exhibitorsearch.messefrankfurt.com

Step‑by‑Step Overview of Custom Mold Development

Let’s break down the mold development process into clear, practical phases so you can communicate precisely with your manufacturing partner and anticipate timing correctly.

1. Concept & Requirements Definition

The first step in custom mold development isn’t machinery — it’s listening and specification gathering.

The supplier’s engineering team must collect:

- Wheel dimensions and specifications (diameter, width, offset, hub bore, bolt pattern)

- Material type preference (forged aluminum, cast aluminum, multi‑piece design)

- Performance requirements (load rating, weight targets)

- Aesthetic and finish requirements (spokes, surface pattern, rivets)

- Volume expectations (single prototype vs. batch production)

Once these inputs are captured, the supplier can create a preliminary CAD (Computer‑Aided Design) model of the wheel, which serves as the foundation for the mold design. metamold.com

Pro Tip: Providing as much detail upfront (drawings, references, use‑case scenarios) significantly cuts down back‑and‑forth revisions and speeds up mold design.

2. Mold Design & Engineering

With the wheel CAD design finalized, engineers convert it into a mold design. This involves:

- Creating a 3D mold model with precise geometry, surface contours, and tolerance allowances

- Running simulation tests (flow analysis, material stress prediction)

- Planning venting systems for casting or material paths for forging

This stage often involves multiple internal reviews and iterations to ensure the design will behave correctly during metal flow or deformation. It’s also where engineers forecast production yield, tool life, and maintenance schedules for the mold.

Typical duration: 1–2 weeks

(This varies with design complexity and required revisions.)

3. Prototype Mold Fabrication

Once the mold design is approved, the physical mold — usually made from high‑strength steel or hardened alloy — is machined using precision tools such as CNC mills, EDM (Electrical Discharge Machining), and grinding machines. metamold.com

The mold may also undergo:

- Heat treatment to improve hardness and lifespan

- Surface polishing or coating to reduce friction and improve wheel finish quality

This phase transforms virtual design files into real tooling ready for trial production.

Typical lead time: 2–4 weeks

Complex designs and tighter tolerances can push this into 4–6 weeks.

4. First‑Article Sample Production

With the physical mold ready, the next step is trial production. Depending on your chosen manufacturing method:

- Casting – molten aluminum is poured into the mold and allowed to solidify into a wheel form; this requires controlled temperature and precise cooling. metamold.com

- Forging – a billet of aluminum is compressed under extreme pressure into the mold, resulting in higher strength and denser metal structure. work-wheels.co.jp

The first articles (samples) are then inspected for:

- Dimensional accuracy

- Surface defects

- Structural integrity

- Balance and tolerance parameters

This is possibly the most critical milestone in your project — a go/no‑go decision point before full‑scale production.

Expected duration: 1–2 weeks

5. Testing & Validation

Sample wheels are subjected to quality checks including:

- Dimensional inspection

- Run‑out and balance testing

- Material integrity analysis

- Appearance evaluation

In regulated markets (especially EU or North America), additional certification testing may be required (e.g., load, fatigue, and impact tests). You should verify with your supplier whether these tests will be provided before ordering — as they influence lead times significantly.

Typical Lead Times & What Affects Them

Understanding the realistic timeline for custom mold development helps you plan your sourcing and inventory more effectively.

Here’s a general expectation range for a custom motorcycle wheel mold project:

| Phase | Typical Duration |

|---|---|

| Requirements & CAD Design | 1–2 weeks |

| Mold Design Engineering | 1–2 weeks |

| Mold Fabrication | 2–6 weeks |

| First‑Article Production | 1–2 weeks |

| Testing & Validation | 1–3 weeks |

| Total | 6–15 weeks |

Note: These ranges depend on complexity, your supplier’s capacity, polishing/finish requests, regulatory test requirements, and whether revisions are needed after initial samples.

How to Shorten Lead Times Without Sacrificing Quality

While custom molds inherently take time, there are proven ways to optimize lead times:

- Provide detailed engineering specs upfront: Clear drawings and references reduce back‑and‑forth revisions.

- Use rapid prototyping (e.g., 3D printed patterns) to confirm design intent before final mold machining.

- Specify acceptable material tolerances early — indecision costs weeks.

- Lock down surface finish expectations early (machined, anodized, painted) to avoid rework later.

- Prefer suppliers with in‑house engineering AND CNC capabilities — fewer handoffs mean faster throughput.

Cost Drivers & Risk Factors You Should Know

Mold costs and timelines are influenced by:

- Design complexity: Highly intricate spoke patterns and multi‑piece wheel designs increase mold machining time and wear cost. metamold.com

- Material choice: Steel molds last longer but take more machining time — aluminum molds are quicker but wear faster. metamold.com

- Revisions: Each redesign or late change in specs adds full cycles of design + machining time.

- Certification testing: Additional compliance testing in certain markets may add 1–3 weeks or more.

Final Thoughts — Planning With Confidence

From buyer to supplier, clarity, communication, and realistic expectations are your greatest assets in custom mold development for motorcycle wheels. By understanding the milestones, typical lead times, and cost drivers outlined above, you can reduce surprises, maintain control over quality, and build stronger, long‑lasting export partnerships.

If you’re preparing for a new model launch, planning seasonal stock, or exploring custom wheel options for your international customers, scheduling mold engineering early in your product roadmap gives you the competitive edge in today’s fast‑moving global market.

👉 Looking to discuss your next custom motorcycle wheel project? Contact our engineering team to review your design specs, lead‑time options, and cost estimate — we can help streamline your path from concept to production.