Introduction

If you’re sourcing custom motorcycle wheels for your shop — whether for cast, forged or laced variants — and especially if you’re importing them from overseas, there are a number of manufacturing, quality‑control and documentation issues you should be aware of. Getting this right matters for delivery time, durability, registration/fitment, and ultimately your reputation with your end customers. In this article we’ll walk you through the manufacturing flow, what overseas buyers should verify, typical red flags in lower‑volume custom wheel production, and how to structure your sourcing process for better outcomes.

1. Understanding the Basic Manufacturing Paths

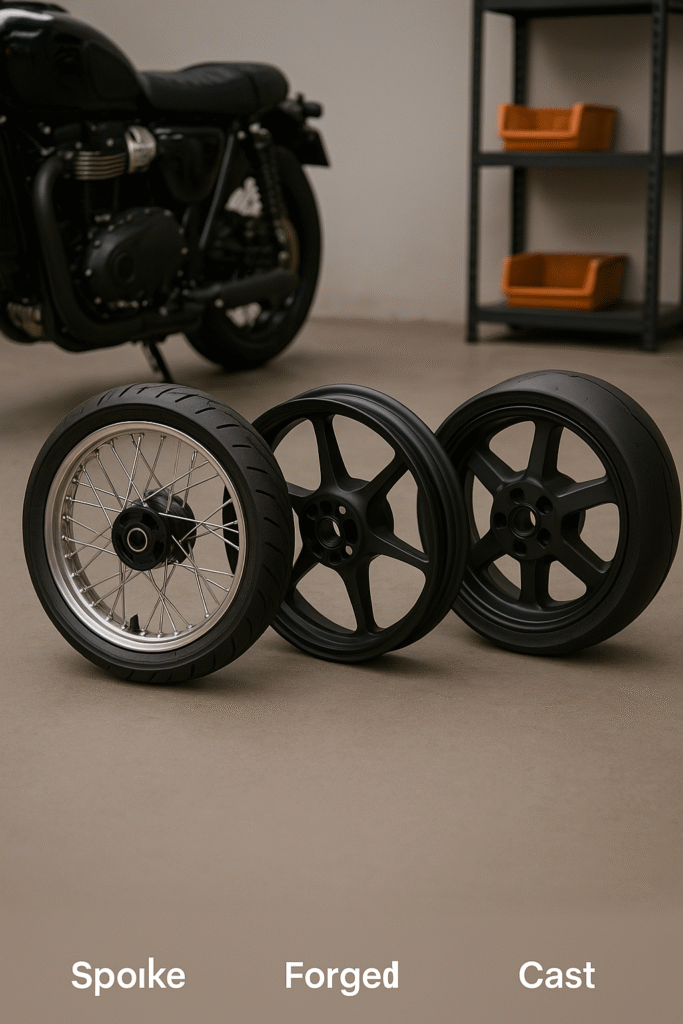

In the custom motorcycle wheel business, there are typically three major manufacturing routes you’ll encounter: cast, forged and laced assemblies. Each has its own implications for quality, cost, lead‑time and suitability for export.

Cast Wheels

These are made by pouring molten aluminum (or alloy) into a mold, then machining to final spec. Because tooling is cheaper and volumes can be higher, cast wheels are generally more cost effective. However, they may exhibit higher porosity or less material uniformity compared with forging.

For example, one custom wheel maker describes their billet process (though for one‐piece machining) as “cut by CNC from 1 piece of solid aircraft‑grade aluminum” when discussing their custom billet wheel production. rotationwheels.com

Forged Wheels

Forging involves shaping the wheel blank under high pressure, which creates better internal grain structure, better strength to weight, and often a premium feel. Machining follows forging to final size, finish and design. If you’re buying from overseas, make sure the supplier shows forging certificates, material trace reports and post‑forge test reports.

For example, forum discussion indicates that machining custom forged wheels requires proper equipment and process:

“Technically, you could make some wheels on any VMC. Its unlikely to be profitable.” Practical Machinist

Which highlights that custom production often demands serious investment and quality control.

Laced / Spoked Wheels

These are assemblies where a rim, hub and a set of spokes or chains are joined (by welding, bolting, etc). These require precision in hub to rim alignment, spoke tensioning, fatigue testing and quality of joining. If you are sourcing laced wheels, ensure the full assembly is tested (not just the rim or hub separately).

2. What Overseas Buyers Should Verify: The Buyer Checklist

When you’re dealing with a supplier overseas (often in Asia, Eastern Europe or elsewhere), here are the key things you as the buyer should ask for and validate proactively. This helps reduce risk, delays and post‑sales issues.

✅ Supplier Credentials & Process Transparency

- Verify the supplier’s business registration and how long they’ve been making wheels (or similar components).

- Ask for quality management certifications (e.g., ISO 9001, IATF 16949) — it shows they have structured processes.

- Ask for their documented process flow: from blank → forging/casting → machining → finishing → assembly → QC → packaging.

✅ Material & Process Documentation

- Material certification: e.g., alloy grade (e.g., 6061‑T6 aluminum), heat‑treatment records, microstructure tests.

- Process traceability: batch or lot numbers, forging/casting heat IDs, machining date, finishing date.

- Non‑destructive testing (NDT) or internal QC reports: hardness testing, ultrasonic testing for casting porosity, etc.

✅ Manufacturing Equipment & Capacity

- Ask for details (or pictures) of their machining equipment: Are they using CNC, 5‑axis, boring machines, vertical/horizontal machines? From the forum discussion: “What kind of machines should be used …? I ordered a sample blank … machining into a 17×4″ rear motorcycle wheel.” Practical Machinist

This indicates that tooling and precision matter. - Ask about their throughput and lead‑time: If they promise too fast for a custom forged wheel, ask deeper questions about process steps.

✅ Testing & Validation

- Ask for test reports: radial fatigue (rim rotation under load until failure), bending fatigue (rim edge loaded repeatedly), impact tests (rim hit at edge, hub load tests).

- Ask for sample certification of a prior run: Did they capture failure data? Do they reuse the same process for your run?

- For custom runs where full certification may not apply (especially for small batches), ask how they validate the design and finish for road use.

- Ask for recorded parameters for your size/offset/bolt pattern: e.g., hub‑bore, PCD (bolt circle), rim width, offset/backspacing, load rating.

✅ Finishing & Appearance

- Surface finishing (machining marks removed, anodising, powder coat, chrome plating) matters for buyer perception.

- Ask about how they control plating thickness, coating adhesion tests, and corrosion resistance. If shipping overseas, you’ll want durable finish with good shipping protection.

- Discuss packaging: custom wheels are often high‑value items; check how they protect rims from damage (e.g., wood crates, foam inserts, desiccant for overseas shipping).

✅ Export / Logistics & Documentation

- Ask for their experience exporting wheels (to Europe/North America/Australia) — a supplier familiar with export lots, duty & customs documentation, can reduce your headaches.

- Ask for Certificate of Origin, export packaging photos, shipping lead‑time, incoterms (FOB, CIF).

- Ask how they handle warranty, spares parts, replacements for shipping. For overseas shipments, a supplier who supports spares globally is a plus.

✅ Customer References & Review

- Ask for previous overseas buyers (especially in your region or markets). Ask for contact or at least documented case studies: e.g., “We shipped 100 wheel sets to a European custom bike shop, all installed and running for the season”.

- Ask for photos of installed bikes, and ideally feedback on performance (fit, finish, durability) and any registration/inspection experience in Europe.

3. Typical Risks & How to Mitigate Them

As a buyer you face several common risks when sourcing custom wheels overseas. Being aware means you can put mitigation in place.

🔻 Risk: Supplier Over‑promises on Lead‑time

Custom wheels (especially forged or one‑off designs) often take multiple weeks: blank procurement, machining, finishing, assembly, inspection, packaging, shipping. If supplier commits to e.g., “4‑week delivery” for a new forged design, ask for schedule milestones: sample first, tooling confirmed, machining done, finishing started. Build in buffer.

🔻 Risk: Quality Variability in Small Batch Production

With low volumes, a supplier may skip some QC steps to reduce cost. As one forum user warns:

“Manufacturing any wheel/brake components in a heavily regulated industry … I would expect to spend 100 k before I am receiving anything in cash.” Practical Machinist

Meaning that small batch production still carries fixed overheads; if not done right you may get inconsistent quality. Mitigate by specifying sample inspection and first‑article inspection before full production.

🔻 Risk: Fitment / Registration Issues in Your Market

Even if the wheel is physically good, your local registration body may raise issues (hub‑to‑rim geometry, load rating not documented, finishing not durable). Mitigate by asking supplier to send you full specification sheet: wheel size, offset/backspacing, hub bore, bolt pattern, load rating, finishing details, installation instructions. Also check with your local authorities (in your market) if any component approval is needed for registration.

🔻 Risk: Shipping Damage or Packaging Delays

Wheels are heavy, large diameter goods, vulnerable to shipping damage especially overseas. Check that packaging is robust, crate meets export standard, and insurance/inspection at loading is provided. Ask supplier for packaging photos and shipping inspection report.

🔻 Risk: After‑Sales & Spare Parts

If a wheel fails or there is damage, you’ll want spare parts or hub/spoke replacements readily available. Ask supplier: what happens if a customer in Europe needs a replacement? Is there a stock of spare parts (hubs, spokes, rims) and what are the lead‑times? This is a trust signal.

4. How to Structure Your Sourcing & Purchase Process

Here’s a recommended procurement flow for an overseas custom wheel purchase, tailored for B2B buyers like you:

- Define your spec: bike model(s), wheel sizes, offset/hub specs, finish, application (road/off‑road/show), quantity.

- Supplier pre‑qualification: Check credentials, ask for process, ask for past references, ask for equipment/inspection photos.

- Request sample / prototype: Before full run, produce one sample wheel. Inspect for machining quality, finish, fitment.

- Production agreement: Specify MOQ, lead‑time, tooling cost (if any), quality control milestones (e.g., first article inspection, batch inspection).

- Documentation delivery: For your import, ask for: drawings, material certificates, process flow sheet, test report summary, packaging photos, export documents.

- Pre‑shipment inspection: Either you or a third‑party agent inspect wheels prior to shipping (dimensions, finish, packaging).

- Shipping & logistics: Confirm incoterms, packaging, insurance, transport modality. For Europe imports, confirm customs classification and any duties/VAT.

- Installation / registration support: Provide your end customers (custom shops) with installation instructions, torque specs, fitment guidelines. If wheels require firm registration or homologation, supply the needed docs.

- After‑sales follow‑up: Track how the wheels perform in the field, gather customer feedback, and ensure spare parts availability is ready.

- Continuous improvement: Based on feedback and performance, refine specs, finishes, and sourcing terms for next batch.

5. Why This Matters for You as a Buyer

From your perspective – managing procurement for a custom shop or importing wheels for resale – investing time in the sourcing phase has high payoffs:

- Better durability and fewer returned goods: High quality manufacturing means fewer problems in the field.

- Fewer registration/import surprises: If the supplier supplies full documentation and the product fits registration requirements in your market, you avoid delays and re‑work.

- Stronger brand reputation: In the custom motorcycle space your clients (builders, riders) expect top quality wheels. Sourcing from a reliable overseas partner ensures you meet those expectations.

- Cost efficiency in long term: Although selecting the right supplier might take more time up front, higher reliability and less waste reduce total cost of ownership.

- Scalable sourcing: If you build a trusted overseas supplier relationship, you can scale future batches, custom sizes and finishes more easily.

Conclusion & Call to Action

Sourcing custom motorcycle wheels from overseas brings many exciting possibilities — unique designs, cost advantages, custom finishes, bespoke sizes. However, as a buyer you must treat the process like a manufacturing procurement project, not a simple catalog order. Verifying manufacturing capacity, process controls, documentation, fitment and after‑sales support are all part of the job.

If you follow the checklist above, you’ll be well‑positioned to select a supplier you trust, minimize risk, and deliver high‑quality wheels to your customers. The next time you’re evaluating a new wheel design, get the documentation, talk to references, inspect a sample, and align the shipping/logistics plan before you commit.