If you’re sourcing forged motorcycle wheels for a custom shop, OEM program, or wholesale channel, the “manufacturing process” isn’t just factory trivia—it directly affects what you care about most: strength-to-weight performance, consistency between batches, lead time reliability, and paperwork accuracy for import compliance.

Many buyers have experienced this: two wheels that look identical on a product page, but one arrives with inconsistent machining, surface defects after coating, or tolerance issues that create fitment headaches and returns. The difference often comes down to how the wheel is forged, machined, treated, and inspected.

This guide breaks down the forged motorcycle wheel manufacturing process step-by-step, in plain English, with B2B sourcing checkpoints you can use to evaluate suppliers—and to communicate requirements clearly for your next order.

What “Forged” Really Means (and Why It Matters)

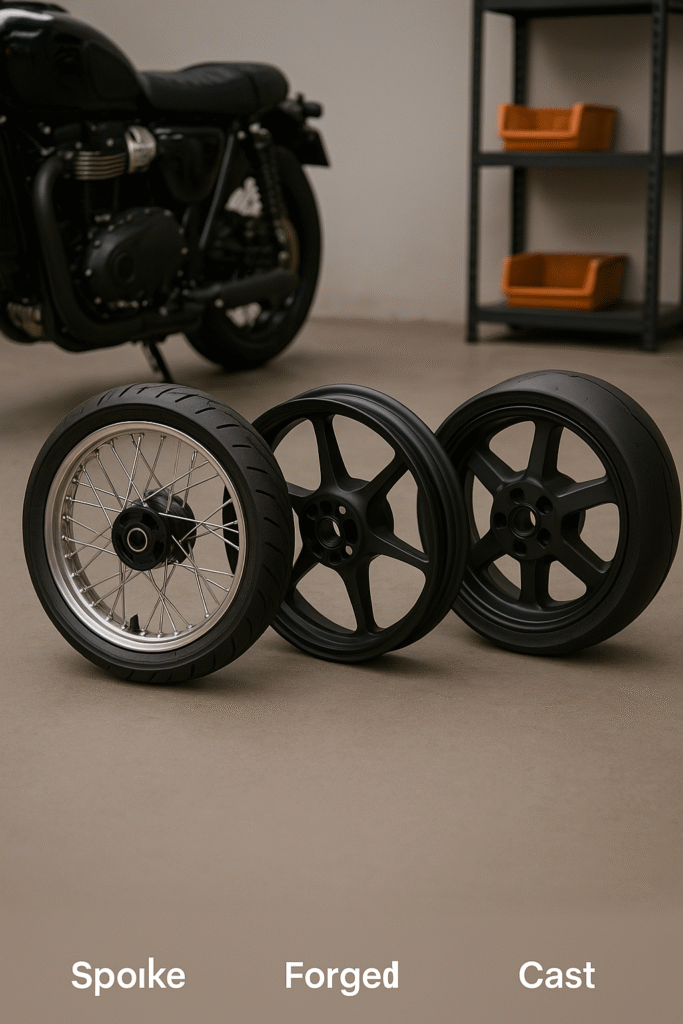

A forged wheel starts as an aluminum alloy billet that is compressed under extreme pressure to form a dense, aligned grain structure. Compared with cast wheels, forging typically delivers:

- Higher strength-to-weight ratio

- Better fatigue resistance (important for performance and long-term durability)

- More consistent material structure (useful for stable machining and finishing)

For B2B buyers, forging is attractive because it can reduce warranty risk and boost premium positioning—especially for performance builds, heavy cruisers, and high-torque applications.

The Forged Motorcycle Wheel Manufacturing Process (Step-by-Step)

1) Engineering & Fitment Confirmation (The Step That Prevents Costly Mistakes)

Before metal is touched, a serious manufacturer confirms the wheel’s key fitment data, such as:

- Wheel size (e.g., 17×3.5, 18×5.5)

- Hub dimensions and bearing seat specs

- Offset requirements

- Brake disc interface / bolt pattern

- Sprocket carrier interface (rear)

- Tire profile goals and clearance

B2B sourcing tip: If a supplier doesn’t ask for fitment specs—or can’t provide a confirmation drawing—expect problems later (rub issues, misalignment, or incorrect mounting).

2) Raw Material Selection (Billet Quality Controls Everything Downstream)

Most forged motorcycle wheels use high-grade aluminum alloys (commonly 6xxx or 7xxx series depending on design and performance target). Material quality affects:

- Consistency during forging

- Heat-treatment response

- Final tensile strength and fatigue life

- Surface quality after machining/anodizing

B2B sourcing tip: Ask for material certification options and batch traceability. It’s a strong trust signal for international buyers.

3) Preforming & Heating (Preparing the Billet for Forging)

The billet is cut to weight, then heated to a controlled temperature range so it can deform properly during forging without cracking. Temperature control here impacts:

- Grain flow quality

- Internal stress distribution

- Repeatability of shape

4) Forging (Where Strength Is “Built In”)

This is the defining stage. Under high tonnage, the billet is pressed into a near-net wheel blank. Common forging approaches include:

- One-piece forging (often associated with high strength and a clean structural path)

- Multi-step forging (used to refine form and improve grain flow)

- Flow forming / rim rolling (in some designs, especially to refine barrel thickness)

The goal is a dense, controlled structure that’s strong without being overly heavy.

B2B sourcing tip: Ask how many forging steps are used, and whether the supplier can share process photos or a basic process sheet for your compliance file.

5) Trimming & Pre-Machining (Removing Excess Material)

After forging, the blank may have flash or extra material that must be trimmed. Pre-machining creates stable reference surfaces so later CNC operations can hold tight tolerances.

6) Heat Treatment (Strength and Stability Are Set Here)

Heat treatment is used to achieve the target mechanical properties and dimensional stability. If heat treatment is inconsistent, you may see:

- Warping during CNC machining

- Unstable tolerances

- Higher risk of fatigue issues over time

B2B sourcing tip: For export buyers, this is a key process to ask about because it affects consistency across production lots.

7) CNC Machining (Where Precision and Customization Happen)

CNC machining turns the forged blank into a functional wheel with exact geometry:

- Hub bore and bearing seats

- Disc mounting faces

- Spoke pocketing (weight reduction)

- Valve hole placement

- Final bead seat contour and runout control

This is also where most customization features come in:

- Custom spoke designs

- Engraving / laser marking

- Special drilling or interface requirements

B2B sourcing tip: If you’re selling into demanding markets, request tolerance targets (runout limits) and inspection methods.

8) Deburring, Surface Prep & Cleaning (Critical for Coating Quality)

Before finishing, surfaces are refined to remove sharp edges and tool marks. Proper cleaning ensures the coating bonds correctly—especially for powder coating or anodizing.

If this step is rushed, you may see:

- Pinholes under coating

- Peeling or adhesion failures

- Inconsistent gloss/texture

9) Finishing Options (Appearance + Protection)

Forged wheels are finished not just for looks, but to protect the surface in real riding environments. Common options include:

- Anodizing (hard, corrosion-resistant, premium look)

- Powder coating (durable, wide color range)

- Brushed + clear coat (premium custom style)

- Polishing (high-end aesthetic, more upkeep)

B2B sourcing tip: Ask for finishing samples and a “finish code system” so your team can reorder accurately without color drift.

10) Quality Inspection (The Difference Between a Supplier and a Partner)

A professional forged wheel QC process usually includes:

- Dimensional checks (critical interfaces)

- Runout checks (radial & lateral)

- Surface inspection after finishing

- Balance validation (depending on program)

- Packaging inspection (export-safe packing)

B2B sourcing tip: Ask whether the factory supports pre-shipment inspection photos/videos and whether inspection records can be supplied per batch.

11) Packaging for Export (Often Overlooked, Always Expensive When Wrong)

Export packaging should protect the wheel from:

- Edge impacts

- Finish scratches

- Humidity exposure (especially sea freight)

Ask about:

- Foam protection

- Individual cartons + master cartons

- Palletization method

- Labeling accuracy (SKU, finish code, size, batch)

What to Ask a Forged Wheel Supplier Before You Place a B2B Order

Here’s a quick checklist you can copy into your RFQ email:

- Can you provide a confirmation drawing for my fitment?

- What alloy do you use, and can you support material traceability?

- What forging method/steps are used?

- What heat treatment process is applied?

- What CNC tolerance targets and runout limits do you control?

- What finishing options are available, and can you provide samples?

- What QC checkpoints are recorded, and can you share inspection records?

- How do you package wheels for international shipping?

- Can you support documentation accuracy for customs clearance?

Why the Process Matters for B2B Buyers

The forged wheel manufacturing process isn’t one single step—it’s a chain. Material quality, forging method, heat treatment, CNC accuracy, surface preparation, finishing, and inspection all affect whether your wheels arrive consistent, fit correctly, and hold up in real riding conditions.

If you’re sourcing for a custom shop, distributor program, or OEM build, the best supplier is the one that can provide:

- Repeatable production quality

- Clear fitment documentation

- Reliable QC + export packaging

- Customization without confusion

Need Forged Wheels With Export-Ready Documentation?

If you want to compare forged wheel specs, confirm fitment, or build a custom wheel program (sizes, finishes, branding, packaging), FLEXIMOTO Wheels LLC can support B2B export orders with customization and process transparency.

Send your fitment requirements (bike model/year, wheel sizes, offset, brake/disc details) and your target market (EU/US/AU/Middle East/Asia). We’ll reply with a practical recommendation and a quotation structure that’s easy to approve internally.