Introduction: Why Wheel Choice Matters More in B2B Than You Think

If you’re sourcing motorcycle wheels for international trade — whether for custom builds, OEM replacements, or premium upgrades — the choice between forged and cast wheels isn’t just a technical matter. It directly affects performance, logistics, documentation, and customer satisfaction across your supply chain.

In B2C markets, riders debate handling or aesthetics. But in B2B export, you’re dealing with a wider set of concerns: compliance with local certifications, durability in harsh conditions, freight costs, and whether your products actually support the success of your downstream partners.

This article breaks down the core differences between forged and cast motorcycle wheels and explains how to choose the right type for your export business — based on practical B2B realities.

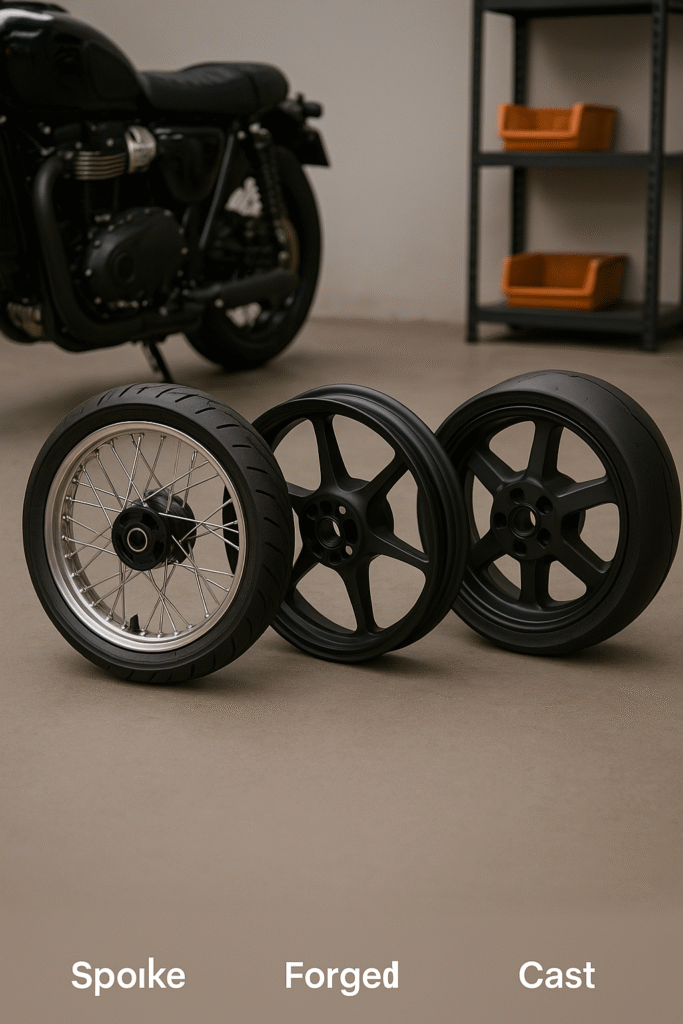

1. The Basics: What Are Forged and Cast Wheels?

Cast Wheels – Reliable and Cost-Effective

Cast motorcycle wheels are made by pouring molten aluminum into a mold. The process is fast, scalable, and allows for intricate designs. Most OEM motorcycles come with cast wheels due to their affordability and appearance flexibility.

Advantages:

- Lower unit cost

- Shorter lead times

- High design flexibility

- Suitable for OEM replacements and everyday use

Limitations:

- Heavier than forged wheels

- Potential for porosity and surface imperfections

- Lower fatigue strength under repeated stress

Forged Wheels – Strength and Precision for Demanding Markets

Forged wheels are produced by applying immense pressure to aluminum billets, shaping the material while refining its grain structure. The result is a lighter and stronger product with higher resistance to impact and fatigue.

Advantages:

- Reduced unsprung weight

- Enhanced durability and longevity

- Improved braking and acceleration

- Ideal for performance and premium custom builds

Limitations:

- Higher production cost

- Longer lead times, especially for customized orders

- Often requires advanced machining and finishing

2. Comparison Table: Forged vs Cast Motorcycle Wheels for Export

| Feature | Cast Wheels | Forged Wheels |

|---|---|---|

| Weight | Heavier | Lighter |

| Strength | Moderate | High |

| Cost | Lower | Higher |

| Customization | Good (design) | Excellent (design + performance tuning) |

| Certification Compliance | Requires more QA | Easier to meet strength-related tests |

| Ideal Use Cases | OEM replacement, scooter/commercial | Racing, custom builds, high-end |

| Shipping Costs | Higher due to weight | Lower per unit |

| Fatigue Resistance | Lower | Higher |

| Market Value | Mid-range | Premium |

3. Why This Matters in B2B Motorcycle Export

Export Logistics

When you’re shipping pallets or containers, every kilogram matters. The weight savings from forged wheels can reduce your freight costs, especially in air shipments or regions with strict shipping quotas.

Compliance and Certification

Markets such as the EU, US, and Australia require ECE, DOT, or JWL certifications. Forged wheels, due to their structural integrity, tend to meet these standards more easily. Cast wheels can comply as well — but only if strict quality control is maintained.

Customization and Branding

Forged wheels are often preferred by workshops and distributors who demand bespoke finishes, custom fitments, or private labeling. These are value-add features that elevate your product line and allow you to serve niche or performance markets.

Aftermarket and Resale

Forged wheels typically retain higher aftermarket value. For distributors or shops that resell parts, this translates into better margins and customer loyalty.

4. Which Wheel Type Suits Your Business Model?

Choose Cast Wheels If You:

- Focus on high-volume, cost-sensitive markets

- Supply commuter or mid-range motorcycles

- Need shorter lead times for fast-moving inventory

- Serve customers with standard OE requirements

Choose Forged Wheels If You:

- Serve premium or custom motorcycle markets

- Target regions with strict quality certifications

- Want lighter wheels for racing, touring, or performance builds

- Offer branded or high-margin products

5. The Hybrid Strategy: Offer Both to Capture the Full Market

Smart exporters don’t choose between cast or forged — they offer both, tailored to customer needs.

For example:

- Use cast wheels for stock replacements and price-sensitive SKUs

- Use forged wheels for premium builds, custom orders, and special editions

This dual offering lets you serve budget-conscious clients and high-end specialists alike. It also increases order flexibility — essential in a global market where one client’s budget is another’s upgrade opportunity.

6. Hidden Factors That Influence Your Decision

Documentation and Traceability

Clients often request test reports, certification numbers, or material specs. Ensure your supplier — cast or forged — can provide proper documentation for customs clearance and insurance compliance.

Lead Times and MOQ

Forged wheels often have longer lead times and higher MOQs, especially for custom configurations. Plan your inventory cycles accordingly, or work with suppliers that offer modular forged designs with flexible finish options.

Freight and Packaging

Forged wheels being lighter means lower shipping costs and less damage risk during transit. Some suppliers also offer custom packaging solutions for better stacking and branding.

7. Real-World Mistakes to Avoid

- Choosing purely based on price — A cheaper cast wheel may cost more in the long run due to warranty claims or reputational damage.

- Ignoring certification needs — Failing to verify documents can delay customs clearance or prevent legal resale.

- Ordering forged wheels without discussing fitment — Many forged options require accurate axle, offset, or hub specs to avoid installation issues.

- Overlooking freight differences — Even a few kilos per wheel adds up across pallets or containers.

Conclusion: Make the Right Choice for Your Market

There’s no one-size-fits-all answer in the forged vs cast motorcycle wheels debate — only what fits your customer base, market demands, and brand position.

- Cast wheels offer a cost-effective, fast-moving option for standard builds.

- Forged wheels provide performance, prestige, and peace of mind for custom and premium markets.

Whether you’re shipping to Europe, Australia, the Middle East, or North America, understanding these trade-offs helps you build better product lines, reduce risk, and strengthen relationships with your buyers.

If you’re exploring both cast and forged solutions for your next shipment, now’s a good time to reevaluate your strategy. Ask the right questions, check the specs, and partner with suppliers who understand B2B export priorities — not just aesthetics.