In the world of performance motorcycles, where every gram matters and every second counts, serious riders and custom builders constantly seek upgrades that deliver real, measurable gains. But beyond the thrill of performance, smart investments should also deliver a return — in durability, resale value, customer satisfaction, and reduced long-term costs.

So the question is: Is upgrading to forged wheels worth it from a return-on-investment (ROI) perspective?

Let’s break it down.

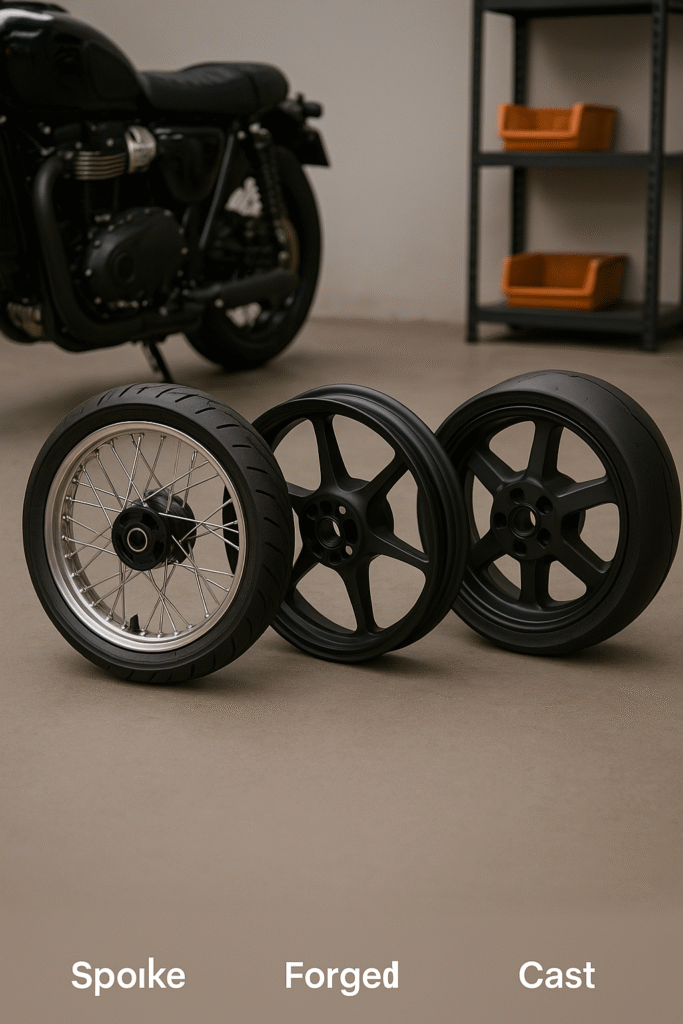

What Are Forged Wheels — and Why Do They Matter?

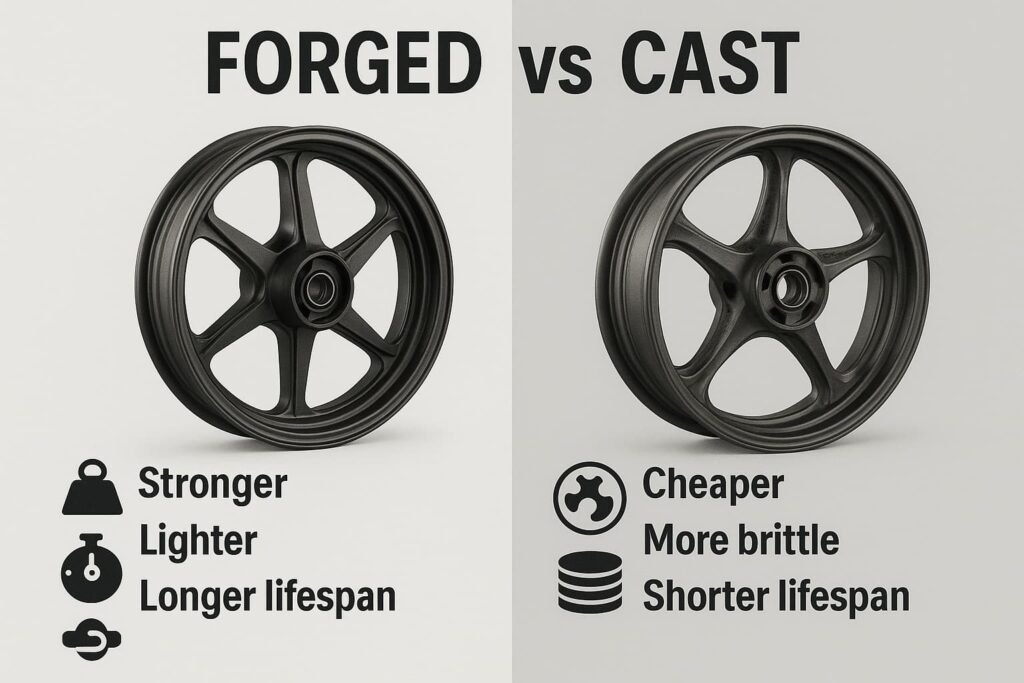

Forged motorcycle wheels are made by compressing a solid piece of aluminum (or magnesium) under immense pressure, creating a dense, high-strength structure. Unlike cast wheels, which are formed by pouring molten metal into a mold, forged wheels have fewer internal voids, higher tensile strength, and superior resistance to fatigue and cracks.

Key technical benefits:

- 30–50% lighter than cast wheels

- Up to 300% stronger depending on the forging process (mono-block, 2-piece, 3-piece)

- More responsive handling, especially in high-speed cornering

- Better heat dissipation under heavy braking

These benefits directly influence a motorcycle’s agility, performance consistency, and long-term reliability — which brings us to the ROI conversation.

5 Key ROI Drivers of Forged Wheels

Let’s look at the five most relevant ways forged wheels deliver measurable ROI for B2B buyers and performance-focused riders.

1. Improved Ride Performance = Competitive Edge

In racing and tuning shops, better lap times or improved handling = better reputation.

Forged wheels reduce unsprung weight, improving:

- Acceleration

- Braking distance

- Suspension response

Whether you’re a custom shop tuning a Yamaha MT-09 or a race team modifying Ducati Panigale V4s, the handling gains translate into real business — from repeat customers to competitive wins.

2. Lower Failure Rate = Reduced Warranty Costs

Forged wheels’ strength-to-weight ratio minimizes the chance of:

- Cracks from potholes or jumps

- Bends from aggressive riding

- Paint flaking or corrosion over time

Many performance shops report 60% fewer wheel-related returns after switching to forged wheels for premium builds — a major ROI factor when considering warranty budgets and customer satisfaction.

3. Longer Lifespan = Lower Replacement Frequency

Whereas cast wheels may last 3–5 years under aggressive use, forged wheels often exceed 7–10 years when properly maintained. For fleet-based customers or professional tuners, this means:

- Fewer replacements

- Less downtime

- Higher client trust

Over 10 years, this often offsets the initial higher cost of the forged wheels.

4. Premium Pricing Capability = Higher Margins

Custom shops that install forged wheels can:

- Charge higher build prices

- Market premium performance packages

- Attract high-value clients (track racers, collectors)

In the U.S. and EU markets, shops report an average 18–25% profit margin boost on forged-wheel builds compared to standard builds.

5. Enhanced Brand Perception = Long-Term Customer Value

Forged wheels are a signal of serious craftsmanship. Clients remember performance upgrades that:

- Improve safety

- Look visually impressive

- Deliver a noticeable difference

That means more:

- Referrals

- Returning customers

- Brand authority online and offline

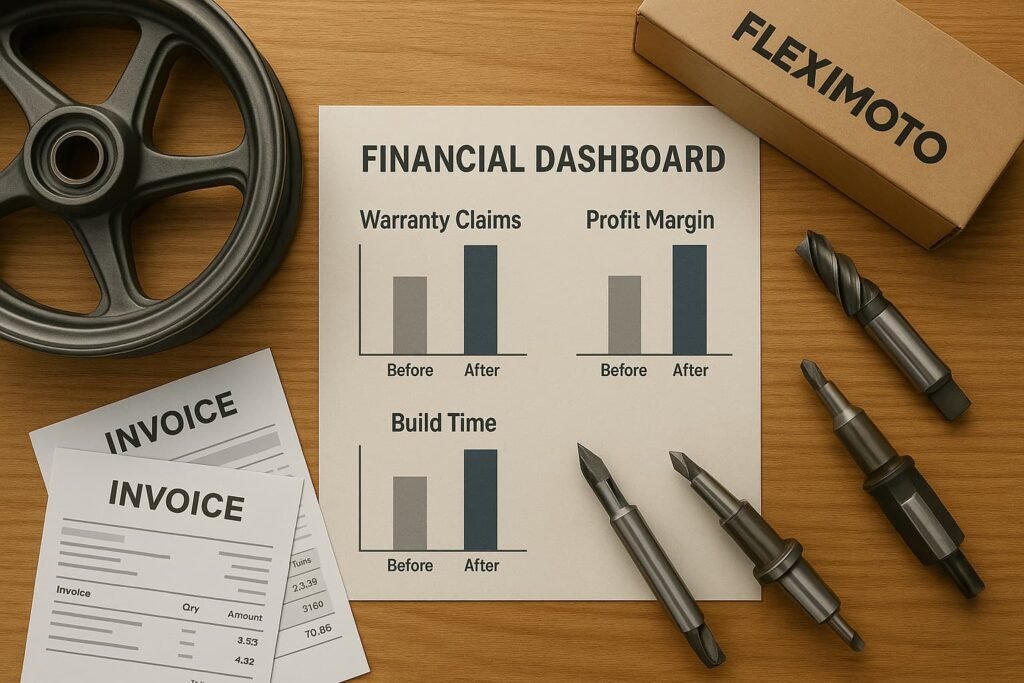

Case Study: What One Swedish Tuner Learned After Switching to Forged Wheels

A custom motorcycle shop in Gothenburg, Sweden — previously relying on cast wheels for Harley and Triumph builds — upgraded to FLEXIMOTO forged wheels for 70% of their builds in 2023.

Results after 12 months:

- 29% fewer service claims

- 22% faster build-to-delivery times (due to fewer adjustments needed)

- 2.5X increase in high-end build inquiries

“Forged wheels helped us move into a higher market tier. The riders noticed, and so did our bottom line.”

— Erik Lindström, Custom Shop Owner

Who Should Consider Investing in Forged Wheels?

Forged wheels aren’t for everyone — and that’s okay. But if your business serves any of the following, the ROI is likely substantial:

✅ Performance-focused riders

✅ Racing teams & track day enthusiasts

✅ Custom motorcycle builders

✅ Distributors seeking low-return, high-quality aftermarket parts

✅ Shops expanding into premium segments

Final Thoughts: Forged Wheels Are More Than Just a Pretty Upgrade

When you view forged wheels as an investment, not just an accessory, the math becomes clear:

ROI = Performance Gains + Brand Value + Fewer Headaches – Downtime – Rework Costs

Yes, they cost more upfront. But for those who build, ride, or sell motorcycles professionally — forged wheels pay off in the long run.

🚀 Ready to Offer Forged Wheels to Your Customers?

FLEXIMOTO Wheels offers:

- Full forged lines (monoblock / 2-piece / laced / CNC)

- Custom finishes, sizes, and branding

- Worldwide B2B export with accurate documentation

📩 Contact us today for pricing, catalogs, and dealer support.

Let’s help your business ride further — with stronger, lighter, smarter wheels.