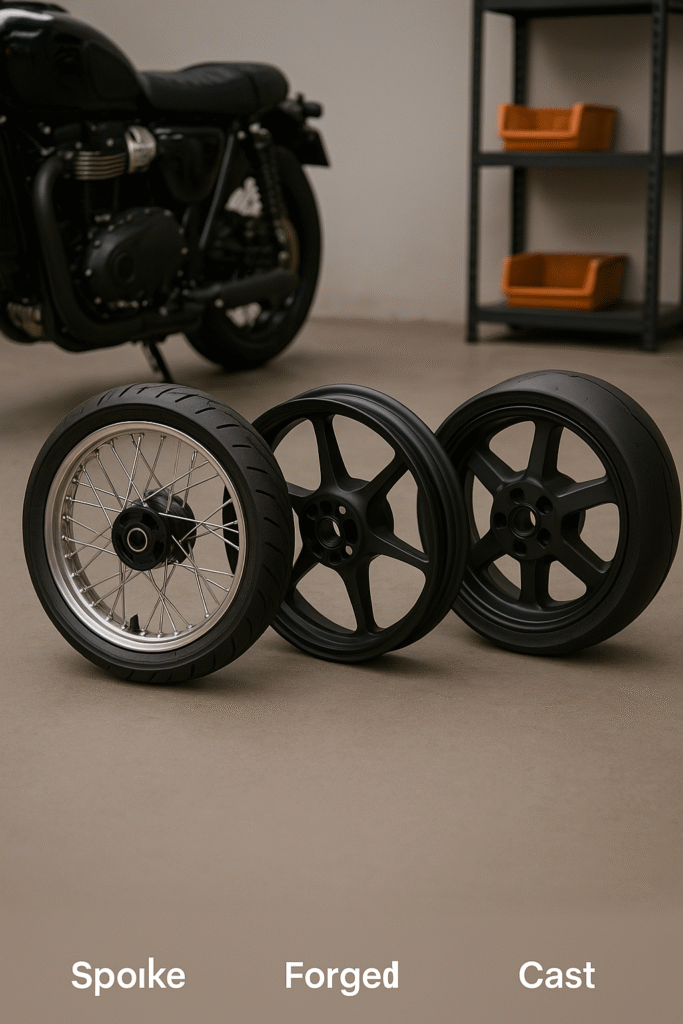

In the world of motorcycle customization, first impressions often start at the wheels. For B2B buyers — whether you’re running a custom workshop, sourcing for a brand, or building your private-label product line — the wheel finish is not just a visual detail, it’s a value signal.

Why?

Because for your end customers, the finish of a wheel communicates everything from craftsmanship and performance intent to aesthetic alignment. But many buyers still face key pain points:

- Color fading or chipping in harsh climates

- Inconsistent finishes across batches

- Limited customization for specific build styles

- Surface defects that erode brand trust

To solve this, it’s essential to work with suppliers who offer technically advanced, visually compelling, and scalable wheel finish options. Below are six of the most impressive finishes currently being used in the custom wheel space — designed to help B2B buyers deliver both performance and premium aesthetics.

🎨 1. Anodized Finish

- Overview: An electrochemical finish where aluminum wheels are treated with vibrant, fade-resistant colors (like gold, red, or titanium grey).

- Why it impresses: The color penetrates the metal, offering better durability and UV resistance than painted options.

- Ideal For: Performance-inspired builds, especially in markets like Europe, Australia, and the Middle East.

- FLEXIMOTO Advantage: Offers both Type II (standard color) and Type III (hard anodized) finishes with precision CNC surface pre-treatment and laser-etched branding. Excellent batch consistency and documentation for export buyers.

🖤 2. Matte Black Powder Coating

- Overview: A dry-coating method using electrically charged powder, heat-cured to form a rugged matte finish.

- Why it impresses: Universally appealing, hides brake dust and scratches well, and exudes stealth and premium vibes.

- Ideal For: Urban café racers, bobbers, and sport naked bikes.

- Notable Suppliers: RCB, Chemco Group

✨ 3. Brushed Aluminum with Clear Coat

- Overview: Wheels are brushed to create a raw metallic texture and sealed with clear protective coating.

- Why it impresses: Retains a handcrafted feel while resisting oxidation. Works well with modern-retro builds.

- Ideal For: BMW R nineT, Triumph modern classics, scramblers.

- Notable Suppliers: Central Wheel Components (UK), Supreme Wheels EU

💎 4. Mirror Polished Finish

- Overview: A labor-intensive, highly reflective chrome-like finish without using actual chrome plating.

- Why it impresses: Creates a show-bike look, popular in high-end custom competitions and luxury cruiser builds.

- Ideal For: Harley-Davidson customs, lowriders, choppers.

- Notable Suppliers: FLEXIMOTO (via custom order), V-Rossi

🔥 5. Two-Tone Contrast Machined

- Overview: Combines anodized or painted background with machined surfaces on spokes or rims.

- Why it impresses: Adds depth, visual complexity, and precision cues that appeal to detail-oriented customers.

- Ideal For: Sport touring, urban builds, and visual “statement” bikes.

- Notable Suppliers: OZ Racing, Excel/Talon Europe

🟠 6. Ceramic-Coated Finish

- Overview: Advanced coating offering heat resistance and anti-corrosion protection with a satin or gloss sheen.

- Why it impresses: Performance customers value its functionality as much as the appearance.

- Ideal For: Enduro and ADV bikes, especially in Southeast Asia and the Middle East.

- Notable Suppliers: FLEXIMOTO (special runs), Haan Wheels

🧭 Conclusion: Finishing Touches That Define Your Brand

In the crowded custom motorcycle space, your wheels are more than functional — they’re the signature of your build or brand. Choosing the right finish can elevate your offering from “just another option” to a premium product that sells itself.

FLEXIMOTO RACING stands out not only for offering a wide range of finishes, but also for delivering reliable consistency, technical documentation, and tailored support for B2B clients worldwide.

📩 Contact us to request finish samples, a custom quote, or technical guidance for your upcoming motorcycle wheel projects.