Choosing between tubeless and tube-type motorcycle wheels isn’t just a “modern vs old-school” debate. It affects how you handle punctures, what tires you can run, how you set up for off-road or touring, and even how your shop manages inventory and customer support.

This guide breaks it down in plain terms—what’s different, what matters in real life, and how to choose the right setup for your bikes or your customers.

What Do “Tubeless” and “Tube-Type” Mean?

Tubeless (TL)

A tubeless setup seals air directly between the tire and the rim. There’s no inner tube. The wheel must have a rim design that can hold air (and a valve stem that seals to the rim).

Tube-Type (TT)

A tube-type setup holds air inside an inner tube, which sits inside the tire. The rim itself doesn’t need to be airtight.

Quick Comparison Table

Tubeless vs Tube-Type at a Glance

| Factor | Tubeless Wheels | Tube-Type Wheels |

|---|---|---|

| Air retention | Tire + rim seal holds air | Inner tube holds air |

| Puncture behavior | Often slow leak (depends on hole) | Often fast leak if tube is pierced |

| Roadside repair | Plug/patch possible (often faster) | Tube replacement/patch usually needed |

| Heat at highway speed | Generally better | Tube adds heat and friction |

| Off-road rock impacts | Can be more sensitive to rim damage (air seal) | Tube can still hold air even if rim is dinged |

| Tire choices | Many modern street tires | Strong for certain off-road / classic tire formats |

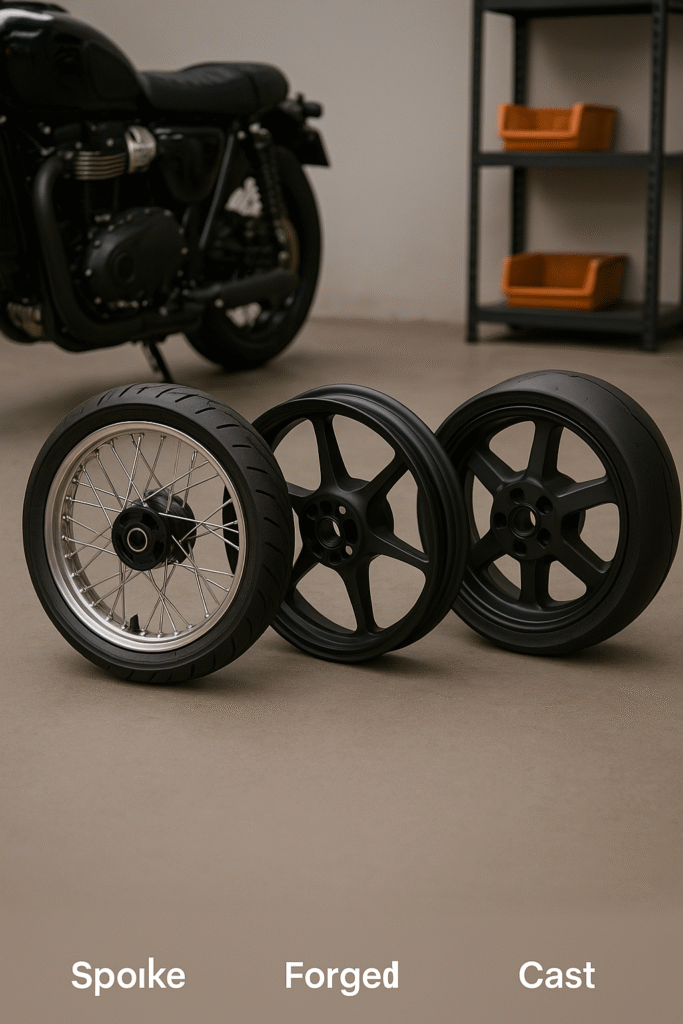

| Rim types | Cast/forged typically, sealed spoked also possible | Spoked rims commonly, many classics |

| Maintenance | Check bead + valve seal | Check tube condition + pinch risk |

How Tubeless Works (And Why Rim Design Matters)

Why tubeless needs a “sealed” wheel

A tubeless rim must:

- Seal at the bead seat (where tire meets rim)

- Seal at the valve stem

- Prevent air loss through spoke holes (if it’s a spoked wheel)

Common tubeless wheel constructions

- Cast wheels (tubeless-ready by design)

- Forged wheels (tubeless-ready by design)

- Sealed spoked wheels (special design like airtight nipples, center-laced designs, or sealing systems)

What can go wrong with tubeless

- A bent rim lip can cause a bead leak

- Poor bead seating can cause slow pressure loss

- Wrong tire fitment can lead to sealing issues

How Tube-Type Works (And Why It’s Still Popular)

Tube-type is straightforward: the tube does the sealing, not the rim.

Where tube-type shines

- Classic bikes with traditional spoked rims

- Certain off-road setups where rim dents happen more often

- Riders who prefer simplicity and universal repair skills

Downsides you should know

- Pinch flats (especially off-road or with low pressure)

- More heat build-up at higher speed

- Fixing a puncture usually means:

- wheel off the bike

- tire bead broken

- tube patched or replaced

Real-World Scenarios: Which One Fits Better?

1) Street + Touring (Highway miles, daily riding)

Tubeless is usually the better choice.

Why:

- Faster roadside fixes (plug kit + inflator)

- Often slower air loss

- Better heat behavior at sustained speed

2) Off-Road / Adventure (rocks, dents, low pressures)

It depends on wheel style and riding intensity.

- Tube-type can be more forgiving if the rim gets dinged

- Tubeless can be great on ADV bikes with properly designed sealed rims, but rim damage can cause bead leaks

Practical tip: if your customers are doing serious off-road and routinely run low tire pressures, make sure they understand pinch-flat risk (tube-type) vs bead-seal risk (tubeless).

3) Custom builds (performance + aesthetics)

Most modern custom street builds lean tubeless, especially with:

- cast wheels

- forged wheels

- properly engineered sealed spoked wheels

Why shops like it: fewer “mystery” tube issues and cleaner service workflow.

Service & Repair: What Shops Care About

Tubeless repair workflow

Typical puncture (nail/screw in tread):

- Remove object

- Ream hole

- Insert plug

- Inflate + check leak

That’s why touring riders love tubeless—less drama on the roadside.

Tube-type repair workflow

Typical puncture:

- Remove wheel

- Break bead

- Pull tube

- Patch/replace tube

- Reinstall and inflate

Doable, but slower, and some riders simply won’t do it on the side of the road.

Safety Notes That Matter (No Scary Talk, Just facts)

Tubeless safety notes

- A sudden large cut can still deflate quickly (same as any tire).

- Bead sealing depends on rim condition and correct tire fitment.

Tube-type safety notes

- Under-inflation increases pinch-flat risk.

- Cheap or old tubes can fail sooner than expected.

Compatibility: Can You Convert Tube-Type to Tubeless?

Sometimes, but not always—and it depends on wheel design.

- Many cast/forged wheels are already tubeless.

- Traditional spoke wheels are not automatically tubeless because air can leak through spoke nipples.

There are sealing methods and systems out there, but from a B2B standpoint the smarter route is usually:

- use a wheel designed for tubeless from the start, or

- stick with tube-type if the wheel is a traditional spoked design without sealing features

Decision Guide

Choose Tubeless if:

- You build/serve street, sport, touring, cruiser markets

- Customers want quick puncture repairs

- You want lower service friction and fewer tube-related issues

- You’re using cast/forged wheels or engineered sealed spoked wheels

Choose Tube-Type if:

- You’re focused on classic spoked setups

- Your bikes see rough off-road impacts

- You want simpler rim requirements (tube does the sealing)

- Tire availability in your segment is mostly tube-type

FAQ

Is tubeless always better?

Not always. For heavy off-road use where rim dents are common, tube-type can still make sense. For most street riding, tubeless is usually easier to live with.

Do tubeless tires cost more?

Sometimes a little, but the bigger cost difference usually shows up in service time and roadside convenience, not just tire price.

Can I run a tube in a tubeless tire?

In many cases, yes (people do this as a workaround), but it’s not ideal unless there’s a clear reason. Always follow tire/wheel manufacturer guidance for safety.

Call to Action: Need Help Choosing the Right Wheel Setup for Your Market?

If you’re sourcing wheels for a custom shop or importing for distribution, the “right” choice depends on your bikes, customer use cases, and what you want to reduce—returns, service time, or fitment headaches.

Tell us:

- bike models + year range

- wheel sizes (front/rear)

- cast/forged/laced preference

- tubeless or tube-type requirement

- your target market (EU/US/AU/Middle East)

We can help you confirm fitment, rim design, and the best wheel structure for your use case—and if you want, we can quote options with lead time and packaging/export docs included.